Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. lihlopha

Ho ea ka bongata ba khabone, tšepe ea carbon e ka aroloa ka mekhahlelo e meraro e latelang:

1) Tšepe e tlaase ea carbon C% ≤ 0.25

2) Tšepe ea khabone e mahareng 0.25

3) Tšepe e phahameng ea carbon C%> 0,6

Lebokose le tlaase

Bohareng ba Carbon

Khabone e phahameng

2. tlhahlobo ea weldability

Palo ea likahare tsa khabone ke sesupo sa bohlokoa bakeng sa nts'etsopele ea lits'ebetso tsa welding.Ha lihlahisoa tsa carbon li ntse li eketseha, matla le boima li eketseha, ha polasetiki le ho tiea li fokotseha, ha khatello ea kelello e ntse e eketseha.Ha re bua ka mokhoa o bapisoang, ha carbon content e le tlase, ho cheseha ho molemo, ka hona, likahare tsa carbon ke tekanyetso ea ho ahlola bothata ba ho tjheseletsa ha carbon steel, 'me mekhoa e fapaneng ea ho tjheseletsa e lokela ho amoheloa bakeng sa likahare tsa carbon tse fapaneng.

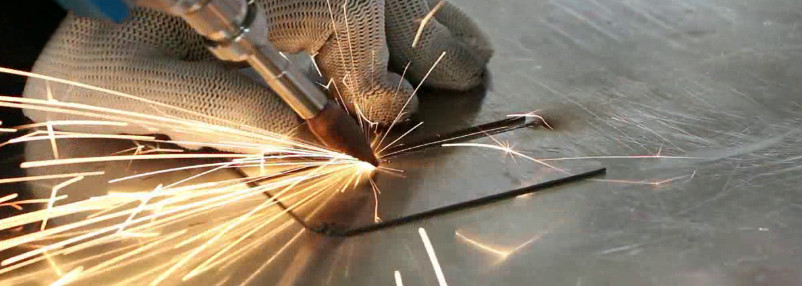

3. Ts'ebetso ea welding

Khetho ea lisebelisoa tsa ho tjheseletsa carbon steel e latela molao-motheo oa "matla a lekanang"

1. Tšepe ea khabone e tlase (eo hangata e tsejoang e le tšepe e bonolo)

Limaraka tse tloaelehileng tsa tšepe tse kang Q235 (tseo pele li neng li tsejoa e le tšepe ea A3), Q255, joalo-joalo, hangata ha li nke mehato e khethehileng ha li cheseletsa, leha e le preheating kapa postheating.

2. Tšepe ea carbon e bohareng

Tšebeliso e tloaelehileng ea tšepe e kang 30 #, 45 #, joalo-joalo, 45 # ke thepa ea ho etsa li-blades sakha le lifaele, ho molemo ho sebelisa lisebelisoa tse tlaase tsa hydrogen tjheseletsa tse nang le khanyetso e ntle ea crack, preheating 100-200 ° C;Haeba ho se bonolo ho futhumatsa pele, ho ka khethoa lisebelisoa tsa tšepe tse se nang tšepe tsa Cr-Ni austenitic.

3. Tšepe e phahameng ea carbon

Limaraka tsa tšepe tse sebelisoang ka tloaelo joalo ka 60Si2Mn, T8, T10 joalo-joalo.60Si2Mn ke tšepe e tloaelehileng ea selemo, ka kakaretso ha e etse kalafo ea tjheseletsa, e sebelisoang haholo joalo ka ho tjheseletsa hape, e lokela ho ba 250-350 ° C preheating, welding e tlameha ho teiloe ka hamore ho felisa khatello ea maikutlo, le kalafo ea 650 ° C kamora mocheso, le eona e ka etsoa. khetha Cr-Ni austenitic lisebelisoa tsa tšepe tse sa jeleng paate

Ea bone, li-electrode tsa letsoho tse bonolo tse hlokahalang bakeng sa ho tjheseletsa:

Mocheso oa ho omisa elektrode

| Ntho | Mofuta oa letlalo | Sehlahisoa | Mocheso | Nako |

| Tšepe ea carbon e tlaase le tšepe e matla e phahameng | Mofuta o tlase oa hydrogen | E7016, E7048, E7015, E7015-G | 300-350 ℃ | 60 mets |

| E7015, E8015-G,E9016-G,E9015-D1,E10015-D2,E12015-G | 330-380 ℃ | |||

| Boima bo phahameng le mofuta o tlase oa hydrogen | E7016-G,E7015-G,E8015-G,E9015-G,E10015-G | 350-380 ℃ | 60 mets | |

| Mofuta oa tšepe o tlase oa hydrogen | E7018、E7018-1 | 300-350 ℃ | 60 mets | |

| E8018-G,E918-G,E9018-M、E10018-D2、E10018M、E11018-G、E11018M、E12018-G | 350-380 ℃ | 60 mets |

2. Mongobo, oli, mafome, joalo-joalo holim'a thepa ea motheo e lokela ho tlosoa

3. Sebelisa mokhoa oa ho khutlela morao ho cheselletsa ho qoba stomata moo ho qalang

Ho lokela ho sebelisoa welding e khuts'oane ea arc, joalo ka likhoele tse oscillating, 'me amplitude ea oscillation ha ea lokela ho feta makhetlo a 3 bophara ba terata.

Nako ea poso: Oct-13-2022