Ka 2010, POSCO ea Korea Boroa, Daewoo Shipbuilding le mekhatlo e mehlano e meholo ea lefats'e ea lihlopha e ile ea qala morero oa "ntlafatso e kopanetsoeng ea tšepe e phahameng ea manganese le lisebelisoa tsa welding bakeng sa mocheso o tlaase haholo", 'me ea finyella tlhahiso e kholo ea tšepe e phahameng ea manganese bakeng sa litanka tsa polokelo tsa LNG. 2015. Ka Phuptjane 2022, ho phunyeletsa botlolo ea tekheniki, Daewoo Shipbuilding & Marine Engineering ea Korea Boroa (DSME) le POSCO e tla tšoara pele lefatšeng ho kenya litanka tsa polokelo ea mafura a manganese LNG ho lijari tse kholo haholo tse tsamaisoang ke LNG. (VLCCs) Mokete, mme e boletse hore e ntlafalitse theknoloji ea ho etsa litanka tsa mafura ho tloha ho tšepe ea pele ho ea ho tjheseletsa le ho etsa.

1. tšepe e phahameng ea manganese ke eng?

Tšepe e phahameng ea manganese bakeng sa litanka tsa polokelo ea LNG ke tšepe ea alloy e nang le dikahare tsa manganese pakeng tsa 22-25%, e nang le khanyetso e ntle ea mocheso o tlase le khanyetso e phahameng ea ho roala, e hlakileng ho feta lisebelisoa tsa khale tsa polokelo ea LNG Ke moratuoa e mocha oa tanka ea polokelo ea LNG. thepa eo Korea Boroa e faneng ka eona ho etsa lipatlisiso le nts'etsopele ka lilemo tse fetang leshome.

2.Tlhahlobo e khuts'oane ea mefuta ea tšepe le melemo le mefokolo ea tsona bakeng sa litanka tsa polokelo ea LNG Lisebelisoa tsa rona tse ts'oanang tsa welding li ka fihlela litlhoko tsena tse thata: Kaha litanka tse kholo tsa polokelo ea mafura a LNG ke lisebelisoa tsa mantlha tsa likepe tse tsamaisang mafura a tikoloho le ketane eohle ea indasteri ea LNG, litekanyetso tsa tekheniki li thata haholo 'me litšenyehelo li theko e boima.LNG hangata e bolokoa le ho tsamaisoa tlas'a mocheso o tlase haholo oa -163 ° C."Khoutu ea Machaba ea Kaho le Lisebelisoa tsa Likepe tse Tsamaeang Likhase Tse Liquefied ka Bulk" e bitsoa "Khoutu ea IGC".Lisebelisoa tse 'nè tsa mocheso o tlase tse ka sebelisoang bakeng sa kaho ea LNG li kenyelletsa: tšepe ea aluminium alloy, Austria Tensitic stainless steel, austenitic Fe-Ni alloy steel (eo hape e tsejoang e le Invar steel) le 9% Ni steel (bona Lethathamo la 1 bakeng sa lintlha tse ling). athe 9%Ni tšepe ke eona e sebelisoang haholo le e sebelisoang haholo bakeng sa litanka tsa polokelo ea mafura a LNG.Empa mefokolo ke hore theko e ntse e phahame, mekhoa ea ho sebetsa e boima, matla a batla a le tlaase, 'me lihlahisoa tsa nickel sehlahisoa li phahame.Lilemong tsa morao tjena, theko ea nickel e 'nile ea tsoela pele ho phahama,' me theko ea lihlahisoa e eketsehile haholo.

Lisebelisoa tsa 4 tsa cryogenic tse ka sebelisoang mohahong oa LNG tlas'a "IGC Code"

| Mocheso o fokolang oa moralo | Mefuta e ka sehloohong ea tšepe le phekolo ea mocheso | Mocheso oa teko ea tšusumetso |

| -165 ℃ | 9% Ni tšepe ea NNT kapa QT | -196 ℃ |

| tšepe e sa hloekang ea austenitic - 304, 304L, 316/316L, 321 le 347 tharollo e phekoloa | -196 ℃ | |

| Aluminium motsoako - 5083 annealed | NO | |

| alloy iron-nickel alloy (36%Ni) |

Papiso ea matla pakeng tsa lisebelisoa tsa LNG tse sebelisoang hangata le tšepe e ncha ea manganese e phahameng

| Ntho | Hangata alloy | tšepe e phahameng ea manganese | ||||

| 9% Ke tšepe | 304 SS | Alu 5083-O | Invar tšepe | MC | ||

| Lisebelisoa tsa motheo | Sebopeho sa Lik'hemik'hale | Fe-9Ni | Fe-18.5Cr-9.25Ni | Al-4.5Mg | Fe-36Ni | M CH mn |

| Microstructure | α1 (+Y) | γ (FCC) | FCC | FCC | FCC | |

| Kotulo MatlaMpa | ≥585 | ≥205 | 124-200 | 230-350 | ≥400 | |

| Matla a tšepe Mpa | 690-825 | ≥515 | 276-352 | 400-500 | 800-970 | |

| -196 ℃TšusumetsoJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| Lichelete | lisebelisoa tsa ho cheselletsa | Inconal | Mofuta oa 308 | ER5356 | - | FCA,SA,GTA |

| Kotulo MatlaMpa | - | - | - | - | ≥400 | |

| Matla a tšepeMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196 ℃TšusumetsoJ | ≥27 | ≥27 | - | - | 27 | |

Mocheso o tlase haholo oa tšepe ea manganese, e kopanyang matla a phahameng, boima bo phahameng le theko e tlase, e na le tebello e pharaletseng ea ts'ebeliso nakong e tlang ea tanka ea polokelo ea mafura ea LNG le ts'ireletso ea tikoloho mebaraka e meng ea tanka ea polokelo ea mafura joalo ka ammonia ea metsi, hydrogen ea metsi, le methanol.

Litlhoko tsa sebopeho le ts'ebetso ea tšepe e phahameng ea manganese

Motsoako oa Lik'hemik'hale (Mokhahlelo oa ASTM)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0,55 | 22.5-25,5 | <0.03 | <0.01 | 3.0-4.0 | 0.3-0.7 |

Boitšoaro ba mechine

● Sebōpeho sa kristale: sefahleho sa li-cubic lattice (γ-Fe)

● Mocheso o lumelletsoeng °-196℃

● Matla a tlhahiso>400MPa (58ksi)

● Matla a ho tiea: 800~970MPa (116-141ksi)

● Teko ea tšusumetso ea Charpy V-notch >41J ho -196℃(-320℉)

Kenyelletso ea lisebelisoa tsa tšepe tse phahameng tsa manganese tse tsamaellanang le welding ea k'hamphani ea rona

Lilemong tsa morao tjena, re inehetse ho etsa lipatlisiso le nts'etsopele ea lisebelisoa tsa tšepe tse phahameng tsa manganese tse tsamaellanang bakeng sa litanka tsa polokelo ea LNG, 'me re ntlafalitse ka katleho lisebelisoa tsa welding tse ka tsamaisanang le thepa ea lisebelisoa tsa tšepe tse phahameng tsa manganese bakeng sa litanka tsa polokelo tsa LNG.Thepa e khethehileng e bontšitsoe ho Lethathamo la 2.

Thepa ea mochini ea tšepe e phahameng ea manganese e tsamaellanang le lisebelisoa tsa tšepe tse kentsoeng

| Lebitso | Boemo | thepa ea mochini | ||||

| YP | TS | EL | -196 ℃ tšusumetso | liteko tsa radiographic | ||

| Lipakane tsa moralo | ≥400 | ≥660 | ≥25 | ≥41 | I | |

| GER-HMA Φ3.2 limilimithara | Li-electrode tsa letsoho | 488 | 686 | 46.0 | 73.3 | I |

| GCR-HMA-S Φ3.2 limilimithara | Metal cored terata | 486 | 700 | 44.5 | 62.0 | I |

Ps.Metal powder core e kentsoeng ka metsing a arc terata bakeng sa tšepe e phahameng ea manganese e amohela flux GXR-200 bakeng sa tšepe e phahameng ea manganese.

Weldability le mohlala oa pontšo ea lisebelisoa tse phahameng tsa tšepe tsa manganese bakeng sa litanka tsa polokelo tsa LNG

The weldability ea tjheseletsa consumables bakeng sa phahameng manganese tšepe ho bontšoa ka tsela e latelang

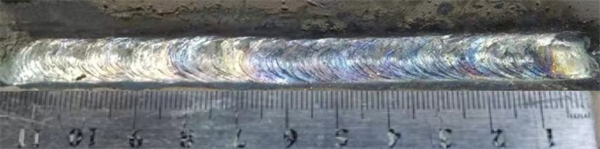

Electrode (GER-HMA) sephara fillet welding ka mor'a ho tlosoa ha slag

Electrode (GER-HMA) elevation angle welding ka mor'a ho tlosoa ha slag

Molamu oa welding (GER-HMA) pele le ka mor'a ho tlosoa ha slag ea fillet

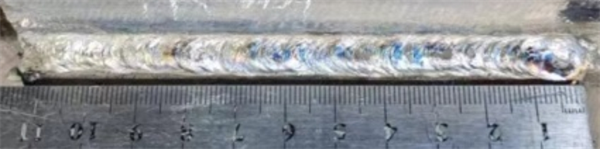

Metal powder core submerged arc (GCR-HMA-S) weld display

Mehlala ea li-welding tse phahameng tsa tšepe ea manganese li kopantsoe ka tsela e latelang

Flat welding (1G) e bonts'a mohlala o tsitsitseng

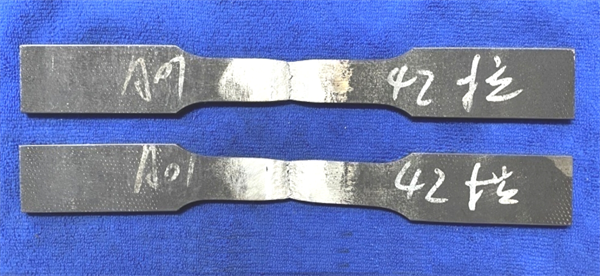

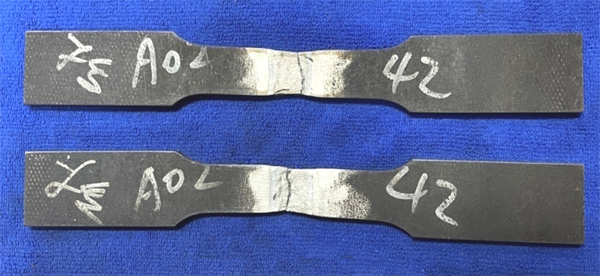

Vertical welding (3G) ponts'o ea mohlala oa tensile

Flat welding (1G) e kobehang mohlala oa ponts'o

Flat welding (1G) e kobehang mohlala oa ponts'o

PS. High manganese tšepe e cheselitsoeng ka lithupa tse cheselletsang 1G le 3G, ha ho mapetsong a sefahleho se kobehang le lisampole tse kobehang ka morao, 'me ho hanyetsa ha crack ho molemo.

Nako ea poso: Nov-22-2022