Websaeteng: www.welding-honest.com +8613252736578

Aluminium e hloekileng ke tšepe e bonolo le e sebetsang hantle.Bakeng sa mehaho e mengata, matla a eona a tlaase.Ho eketsa matla a aluminium, likarolo tsa alloy li hloka ho eketsoa.Koporo, silicon, manganese, magnesium le zinki li sebelisoa e le ntho ea mantlha ho bapala matla a ho qhibiliha a tiileng.Aluminium le alloy alloy li 'nile tsa sebelisoa haholo liindastering tse ngata.

Ho tjheseletsa ha aluminium le alloy alloy ho thata ho feta tšepe e tlase ea khabone.Litšobotsi tsa eona tsa welding li fapane le tšepe e tlase ea carbon.Tshebetso e khethehileng ke e latelang:

1. Soferality ea welded e kopanyang ts'ebetso ea mochini, e fokotsehile khanyetso ea kutu.

2. Ts'ebetso ea lik'hemik'hale e matla haholo, 'me bokaholimo bo thehoa habonolo.

3. matla a mocheso conductivity, 'me ho bonolo ho etsa hore ho insoluble ketsahalo nakong tjheseletsa.

4. Litšitiso tse latellanang tse kang li-pores, mapetsong, ho loma ka thōko, li-slag le ho etsa weld.

5. Khoeli e kholo ea katoloso ea mohala (hoo e ka bang makhetlo a 2 a tšepe e tlaase ea carbon), e atisang ho phunya le ho senyeha nakong ea ho cheselletsa.

6. Thermal conductivity e kholo (hoo e ka bang makhetlo a 5 a tlaase-carbon tšepe).Ka lebelo le ts'oanang la ho tjheseletsa, ho kenya mocheso ka makhetlo a 2 ho isa ho a 4 ho feta tšepe ea welding.

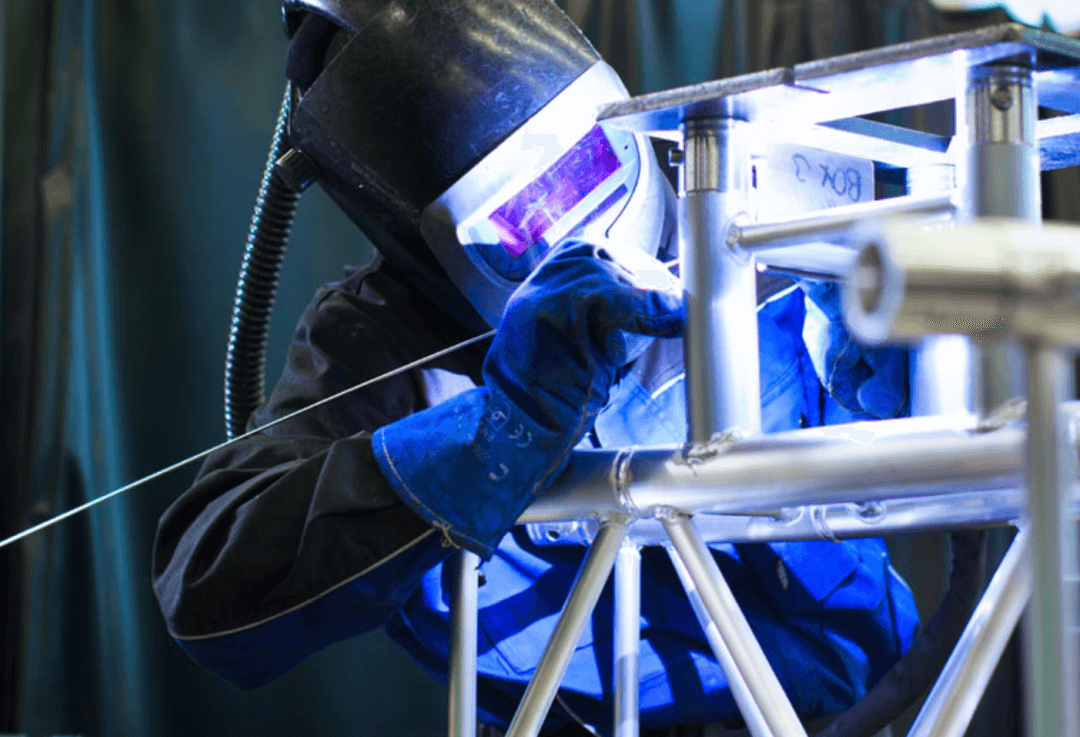

Aluminium alloy e cheselitsoe ka TIG kapa GMAW.

1.Aluminium alloy tig welding

Haeba u hloka ho fumana welding ea boleng bo holimo, Tig welding hangata ke khetho ea pele.Mokhoa o nepahetseng ka ho fetisisa oa ts'ebetso ke ho fapanyetsana welding ea TIG le AC pulse TIG welding.Ho na le melemo e mengata:

1. Ha ho chesoa, litšobotsi tsa cathode atomization li ka tlosoa ka boeona.

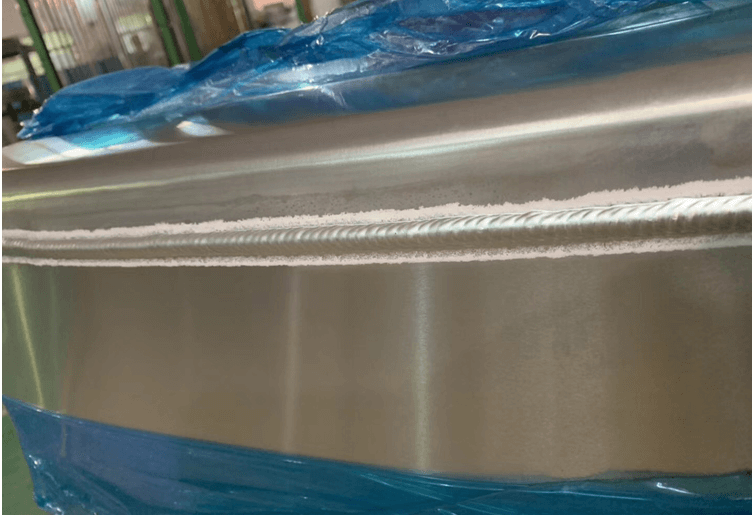

2. Foromo ea ho hokahanya ha e na moeli, bokaholimo bo boreleli ebile bo molemo bakeng sa ho bopa.

3. Sebaka sa tjheseletsa sa moea ho pholisa manonyeletso ho pholile le ho ntlafatsa mokhatlo le tshebetso.

Ka hona, ts'ebetso ena e loketse haholo indastering ea maemo a holimo le ea bohlokoa haholo ea sefofane.Ha e le hantle, mefokolo ea eona e boetse e totobetse haholo.Ts'ebetso ea welding e tlase, 'me ha e loketse tlhahiso ea matla a maholo a phahameng.

1. Aluminium alloy GMAW welding

Gmaw welding e kene butle-butle bophelong ba rona.Khokahano ea reverse ea DC hangata e sebelisoa nakong ea welding, 'me welding ea pulse le eona e ka sebelisoa.Ha ho bapisoa le welding ea TIG, welding ea GMAW e na le melemo e latelang:

1. Ho na le hoo e ka bang ha ho cheso ea oxidative nakong ea ts'ebetso ea welding, 'me mokhoa ona o bonolo.

2. Tlhahiso e phahameng ea basebetsi.

3. U se ke ua amohela lipalo tsa tungsten, theko e tlaase.

Ha welding ho GMAW, ela hloko lintlha tse latelang:

1. U hloka ho sebelisa hose ea silika e entsoeng ka polasetiki, 'me hose ea tšepe e ke ke ea sebelisoa.

2. Mohala oa ho tjheseletsa oa aluminium o bonolo 'me ho tsamaisoa ha terata ho fokola.U hloka ho khetha lebili la terata ea sebopeho sa U-shaped groove.

3. Sebelisa molomo oa conductive oa ka hare o loketseng.

4. U se ke ua arolelana likarolo tse nang le welding ea tšepe ho qoba tšilafalo.

GMA-A5356 e sebelisa phello sebakeng sa bareki

Lintlha tsena li arolelana le basebelisi ba ntseng ba tsoela pele kapa ba seng ba le mothating oa ho chesetsoa, ho re lumella ho hatela pele tseleng ea aluminium alloy welding.

Lihlahisoa tse tloaelehileng tsa phepelo ea k'hamphani ea rona ke tse latelang:

KHOTSO MIG

GTA-A4043 GMA-A4043

GTA-A5183 GMA-A5183

GTA-A5356 GMA-A5356

Nako ea poso: Nov-14-2022