I. Kakaretso

Ka nts'etsopele e potlakileng ea lisebelisoa tsa machaba tsa lik'hemik'hale le matla, litanka tsa polokelo ea tšepe le lijana li sebelisoa haholo ho tsamaisa le ho boloka lik'hemik'hale, lijo le seno, matla le lisebelisoa tse ling.Ka lebaka la matla a eona a matla a tlase a mocheso le ho hanyetsa ho hotle ha kutu, tšepe ea austenitic e sebelisoa haholo kahong ea litanka tsa polokelo ea cryogenic, lisebelisoa le meaho e meholo ea cryogenic.

Tanka ea polokelo ea cryogenic

2. Kenyelletso e khuts'oane ea -196 ℃ mocheso o tlase o ama lisebelisoa tsa tšepe tse sa jeleng paate

| Sehlopha | Lebitso | Mohlala | Standard | Ela hloko | |

| GB/YB | AWS | ||||

| Electrode | Tlhaloso: GES-308LT | A002 | E308L-16 | E308L-16 | -196℃≥31J |

| Flux terata | GFS-308LT | - | TS 308L-F C11 | E308LT1-1 | -196℃≥34J |

| Mohala o tiileng | Tlhaloso: GTS-308LT (TIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J |

| GMS-308LT (MIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J | |

| BONA | GWS-308/ GXS-300 | - | S F308L FB-S308L | ER308L | -196℃≥34J |

3.Motlakase oa rona oa GES-308LT (E308L-16)

Bakeng sa ho fihlela tlhoko ea 'maraka, k'hamphani ea rona e thehile mefuta e fapaneng ea mocheso o tlase haholo, li-electrode tsa tšepe tse sa hloekang tsa austenitic tse thata, sebopeho sa lik'hemik'hale tsa tšepe e behiloeng (joalo ka ha ho bonts'itsoe ho Lethathamo la 1) le thepa e tsitsitseng ea mochini (joalo ka ha ho bonts'itsoe ho Lethathamo. 2), 'me e na le ts'ebetso e ntle haholo ea ts'ebetso ea li-welding tsa maemo ohle Ts'ebetso, le ts'ebetso e matla ea mocheso o tlase, phello ea palo ea eona ea ferrite boleng ba tšusumetso (Letlapa la 3).

1.Motsoako oa lik'hemik'hale oa tšepe e behiloeng

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 | 0.5-2,5 | 1.0 | 0.030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Mohlala 1 | 0.022 | 1.57 | 0.62 | 0.015 | 0.006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Mohlala2 | 0.037 | 2.15 | 0.46 | 0.018 | 0.005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Mohlala3 | 0.032 | 1.37 | 0.49 | 0.017 | 0.007 | 11.79 | 18.66 | 0.021 | 0.027 | 0.048 | 0.6 |

Lethathamo la 1

2.Mechanical thepa ea tšepe depositi

| E308L-16 | Khefutsa MPa | Tensile MPa | Elongation % | -196℃tšusumetso J/℃ | GB/T4334-2020 E Intergranular corrosion | Rtlhahlobo ea adiographic | Ela hloko | |

| Boleng bo le bong | Boleng ba kakaretso | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Mohlala 1 | 451 | 576 | 42 | 32/32/33 | 32.3 | tšoanelehang | I | - |

| Mohlala2 | 436 | 563 | 44 | 39/41/39 | 39.7 | tšoanelehang | I | - |

| Mohlala3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | tšoanelehang | I | - |

Lethathamo la 2

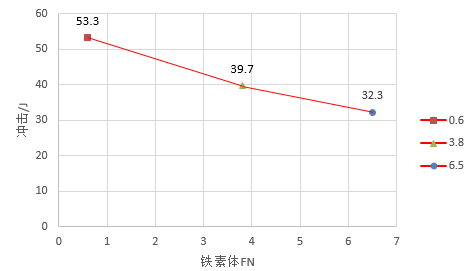

3.Phello ea palo ea ferrite ea tšepe e behiloeng ka tšusumetso

4. Pontšo ea ts'ebetso ea welding (φ3.2mm)

Welding e otlolohileng pele le ka mor'a ho tlosoa ha slag (DC+)

Ho tjheseletsa liphaephe pele le ka mor'a ho tlosoa ha slag (DC+)

4. Litlhokomelo bakeng sa welding e otlolohileng

1. Ho lokela ho sebelisoa welding e tlaase hona joale;

2. Boloka arc ka tlase kamoo ho ka khonehang;

3. Ha arc e fetoha mahlakoreng ka bobeli a groove, emisa ka nakoana, 'me bophara ba ho sisinyeha bo laoloa ka hare ho makhetlo a 3 bophara ba electrode.

5.Pipeline foto ea welding consumables kopo

Bakeng sa -196 ℃ mocheso o tlase oa ts'ebeliso ea lisebelisoa tsa tšepe tse se nang tšepe, kamora lilemo tsa lipatlisiso le nts'etsopele ea lisebelisoa tsa welding, re se re ntse re e-na le lisebelisoa tse ts'oanang tse ts'ehetsang bakeng sa lithupa tsa welding, li-cores tse tiileng, li-flux cores le li-arcs tse koahetsoeng ke metsi, 'me re ntlafalitse li-electrode tse tsoelang pele tsa letsoho. li-welding consumables bakeng sa li-welding tsa maemo ohle, 'me li na le likatleho tse ngata tsa kopo ea boenjiniere, amohela bareki ho buisana le ho khetha!

Nako ea poso: Dec-16-2022