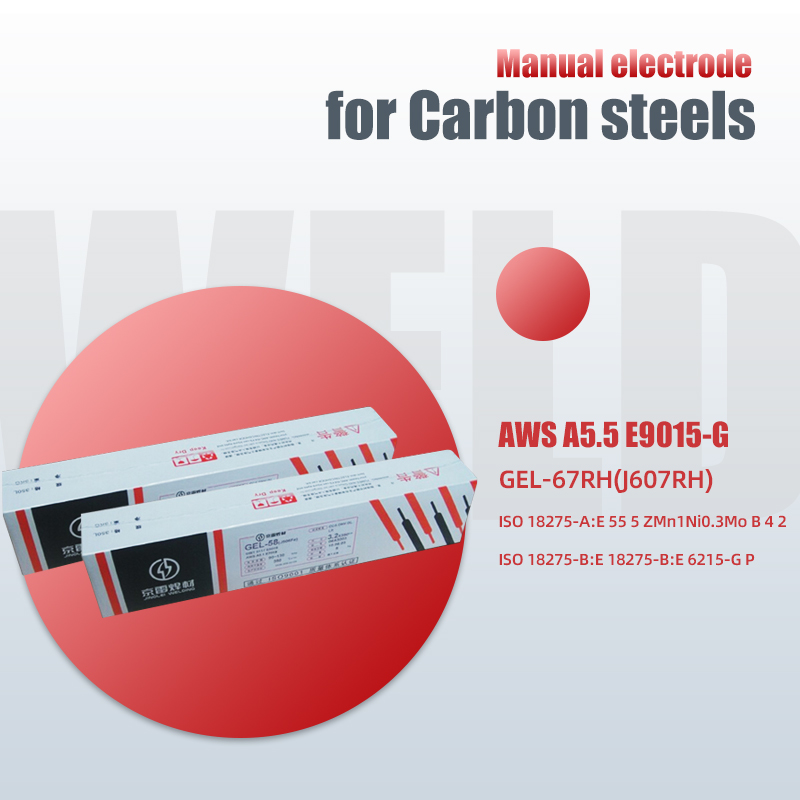

High Carbon steels Manual electrode E9015-G Seal makings

E loketse tšepe e tlase ea alloy, tšepe e mahareng le e phahameng ea khabone le welding ea tšepe, joalo ka mechini ea kaho, mechini ea boema-kepe le liketsahalo tse ling.E boetse e sebelisoa ka tšepe ea pipeline ea X80.

Tekanyetso eo re kopaneng le eona: GB/T32533 E5915-G P, AWS A5.5 E9015-G & A5.5M E6215-G, ISO18275-A:E 55 5 ZMn1Ni0.3Mo B 4 2, ISO 18275-B: E6215-G P.

Ke eng tse

characieristics?

●Electrode e tlase ea sodium hydrogen, arc e tsitsitseng, ho phatloha ho honyenyane, sebopeho se setle.

●Ho bonolo ho etsa desagging, ts'ebetso ea X-ray e ntle.

●Matla a phahameng, haedrojene e tlase.

●Khanyetso e ntle ea crack, botsitso ba mochini.

Parameter ea lihlahisoa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| MOLAO OA MOLAO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| MOHLALA BOHLOKOA | 0.070 | 1.55 | 0.32 | 0.031 | 0.82 | 0.31 | 0.012 | 0.005 | 0.03 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 490 | 590 | 620*1 | 27/-20 | 16 | ||||

| MOLAO OA MOLAO | 530 | 620 | 620*1 | - | 17 | ||||

| MOHLALA BOHLOKOA | 585 | 670 | 620*1 | 85/-50 | 24 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Shebang tsela

re tsamaisa

●Sepalangoang sa makoloi

●Ho tsamaisa ka sekepe

Sheba

ntlo ea rona

Merero

re kenya letsoho ho

●Jiangsu Donghua Energy 80,000 m3 tanka ea polokelo ea propane

●Lisebelisoa tsa ho cheselletsa li-alloys tsa aluminium

Lihlahisoa tsa rona

lefatsheng

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| MOLAO OA MOLAO | - | ≥1.01 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.11 |

| MOHLALA BOHLOKOA | 0.068 | 1.258 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 490 | 590 | 620*1 | 27/-20 | 16 | ||||

| MOLAO OA MOLAO | 530 | 620 | 620*1 | - | 17 | ||||

| MOHLALA BOHLOKOA | 600 | 685 | 620*1 | 85/-50 | 24 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||