TIG Welding Wire Bakeng sa Stainless Steel ER410 Aluminium welding material

THEKNOLOJI CHESE

Se lumelle lipotso

Tsoela pele ho u hlorisa

Arc ho hloka botsitso

Ho bopa ho sa kgahliseng

Spatter e feteletseng

Hangata e sebelisoa liteisheneng tsa motlakase oa metsi le li-valve le

tse ling tse apereng le ho hanyetsa kutu, joalo ka 1Cr13(SUS410).

E ka hanela khatello ea maikutlo ea ho bola e bakoang ke sulfide tikolohong ea oli e tala e nang le asiti

Ripple hantle

Hape e ka hanela mocheso o phahameng oa oxidation ka tlase ho 800C

Arc e tsitsitseng, sebopeho se setle, se nang le ts'ebetso e ntle ea ts'ebetso ea welding.

Slagging e bonolo

Parameter ea sehlahisoa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Tse ding |

| GB/T MELAO | 0.1 | 0.48 | 0.27 | 0.02 | 0.009 | 0.08 | 12.16 | 0.01 | - |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | Elongation/% | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | |||||

| GB/T MELAO | - | 780 | 23 | - | 745*1 | |||||

Tšehetso ea fektheri

Sehlahisoa se loketse bakeng sa a

mefuta e mengata ea likopo

THEKNOLOJI CHESE

Tanka ea ente ea polokeho

-

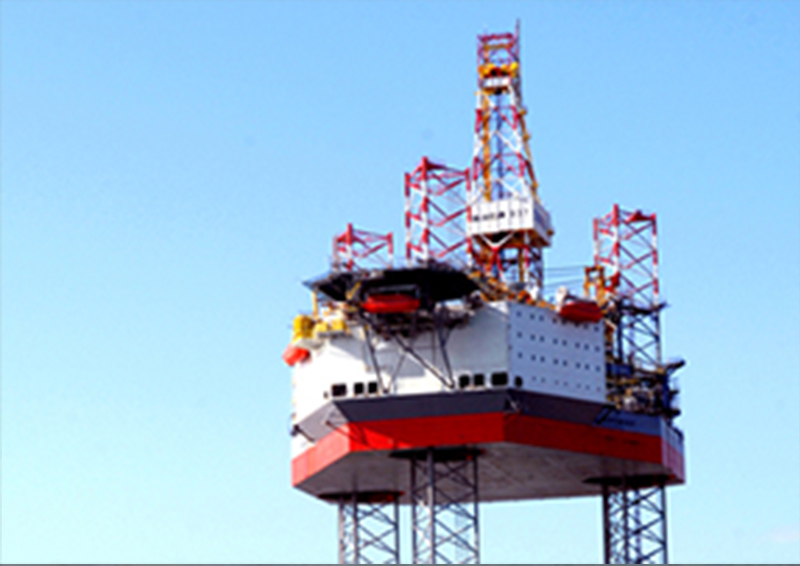

JU2000E sethala sa ho phunya jack-up

-

Lithane tse 37,000 sekepe se akaretsang sa thepa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Tse ding |

| GB/T MELAO | 0.1 | 0.48 | 0.27 | 0.02 | 0.009 | 0.08 | 12.16 | 0.01 | - |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | Elongation/% | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | |||||

| GB/T MELAO | - | 780 | 23 | - | 745*1 | |||||

Ngola molaetsa wa hao mona mme o re romele wona