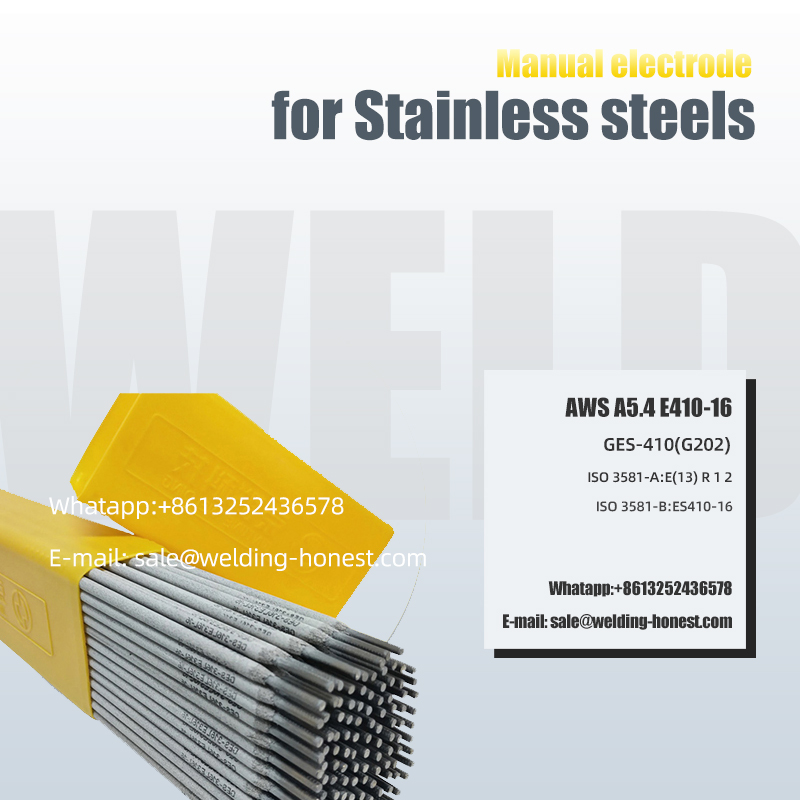

Lisebelisoa tse sa hloekang Manual electrode E410NiMo-16 Soldering jointing

Kopo

E loketse ho roala li-valve tse batloang haholo le ho hanyetsa kutu, rotor ea hydraulic turbine le welding e 'ngoe.

Sehlopha sa setifikeiti:JIS

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T MELAO | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0,70 | 0.04 | 0.03 | 0.75 | |

| MOLAO OA MOLAO | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0,70 | 0.04 | 0.03 | 0.75 | |

| MOHLALA BOHLOKOA | 0.028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0.026 | 0.007 | 0.13 | |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||||

| GB/T MELAO | - | 760 | 595-620x1 | - | 10 | ||||||

| MOLAO OA MOLAO | - | 760 | 595-620x1 | - | 15 | ||||||

| MOHLALA BOHLOKOA | - | 925 | 620x1 | - | 17 | ||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Titanium-calcium martensitic stainless steel electrode, sebopeho se seholo ke 11.5%Cr-4.5%Ni-0.55%Mo;

Ka lebaka la ho eketsoa ha motsoako oa alloy NiMo, ho hanyetsa ha kutu ho tsitsitse haholoanyane, ho thatafala le ho hanyetsa mocheso o phahameng oa mocheso ho ntlafatsoa, 'me ho phatloha ho batang ho thibeloa ka katleho. Boima ba weld bo ka ba 270HB.

Arc e tsitsitseng, sebopeho se setle, ripple e tiea, ho phatloha ho honyenyane, ho tlosoa ha slag habonolo, ho hanyetsa mollo o motle, ho hanyetsa porosity e ntle.

Ningbo Honest Metal Materials Co, Ltd.ke k'hamphani ea machaba ea litsebi tsa ho cheselletsa ka har'a lipatlisiso le nts'etsopele e ikemetseng, tlhahiso, thekiso le tsamaiso. E thehiloe ka 2020.

Lithane tse 9,000 tsa lik'hemik'hale

Zhejiang Petrochemical ea lithane tse limilione tse 40 ka morero oa ho kopanya mochini oa tlhoekiso

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Ho boloka mocheso o tlase le setshelo sa lipalangoang

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T MELAO | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0,70 | 0.04 | 0.03 | 0.75 | |

| MOLAO OA MOLAO | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0,70 | 0.04 | 0.03 | 0.75 | |

| MOHLALA BOHLOKOA | 0.028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0.026 | 0.007 | 0.13 | |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||||

| GB/T MELAO | - | 760 | 595-620×1 | - | 10 | ||||||

| MOLAO OA MOLAO | - | 760 | 595-620×1 | - | 15 | ||||||

| MOHLALA BOHLOKOA | - | 925 | 620×1 | - | 17 | ||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||