Lisebelisoa tse sa hloekang Manual electrode E312-16 weld fabrication makings

Kopo

E loketse mefuta eohle ea lisebelisoa tsa tšepe tseo ho leng thata ho li tjheseletsa le ho phunyeha habonolo kapa ho bonolo ho etsahala pores, ho thatafatsa tšepe ea motsoako joalo-joalo. Le tšepe e phahameng ea k'habone, tšepe ea lisebelisoa le welding ea tšepe e sa ts'oaneng.

Tekanyetso eo re kopaneng le eona: GB/T983 E312-16, AWS A5.4 E312-16 & A5.4M E312-16, ISO3581-A:E(29 9) R 1 2, ISO3581-B:ES312-16

Sehlopha sa setifikeiti: CE

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T MELAO | 0.15 | 0.5-2,5 | 1.00 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.04 | 0.03 | 0.75 | |

| MOLAO OA MOLAO | 0.15 | 0.5-2,5 | 1.00 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.04 | 0.03 | 0.75 | |

| MOHLALA BOHLOKOA | 0.05 | 1.2 | 0.6 | 28.5 | 8.5 | 0.01 | 0.02 | 0.003 | 0.01 | |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | - | 660 | - | 15 | ||||

| MOLAO OA MOLAO | - | 660 | - | 22 | ||||

| MOHLALA BOHLOKOA | - | 740 | - | 24 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| Bolelele bo omileng (mm) | 15-20 | 18-25 | ||||||

| Phallo ea khase(l/min) | 15-25 | 15-25 | ||||||

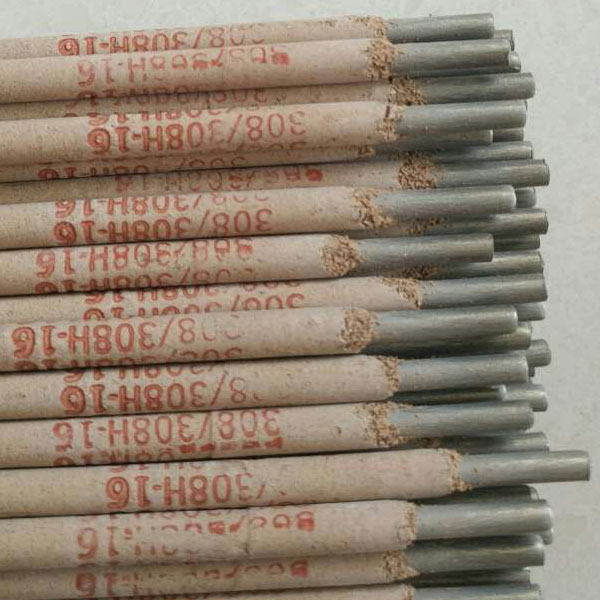

Titanium calcium tšepe e sa hloekang e nang le electrode ea letsoho, weld bakeng sa sebopeho sa austenite-ferrite biphase, sebopeho se seholo ke 29% CR-9% Ni, e tsejoang ka hore ke: electrode ea bokahohle.

Arc e tsitsitseng, sebopeho se setle, li-ripples tse ntle, li-splashes tse fokolang, li-slagging tse bonolo, khanyetso e ntle ea mollo ea letlalo la lithethefatsi, khanyetso e ntle ea stomatal.

Thepa e tsitsitseng ea mochini, sekhahla sa ho feta sa X-ray se phahame.

Ningbo Honest Metal Materials Co, Ltd.ke k'hamphani ea machaba ea litsebi tsa ho cheselletsa ka har'a lipatlisiso le nts'etsopele e ikemetseng, tlhahiso, thekiso le tsamaiso. E thehiloe ka 2020.

Lithane tse 400,000 tse tsamaisang tšepe tse kholo haholo

Tšebeliso ea matla a futhumatsang

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Setshelo sa polokelo ea cryogenic

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T MELAO | 0.15 | 0.5-2,5 | 1.00 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.04 | 0.03 | 0.75 |

| MOLAO OA MOLAO | 0.15 | 0.5-2,5 | 1.00 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.04 | 0.03 | 0.75 |

| MOHLALA BOHLOKOA | 0.065 | 1.45 | 0.75 | 29.2 | 9.5 | 0.02 | 0.029 | 0.008 | 0.10 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | |||||

| GB/T MELAO | - | 660 | - | - | 15 | |||||

| MOLAO OA MOLAO | - | 660 | - | - | 22 | |||||

| MOHLALA BOHLOKOA | - | 805 | - | - | 24 | |||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||