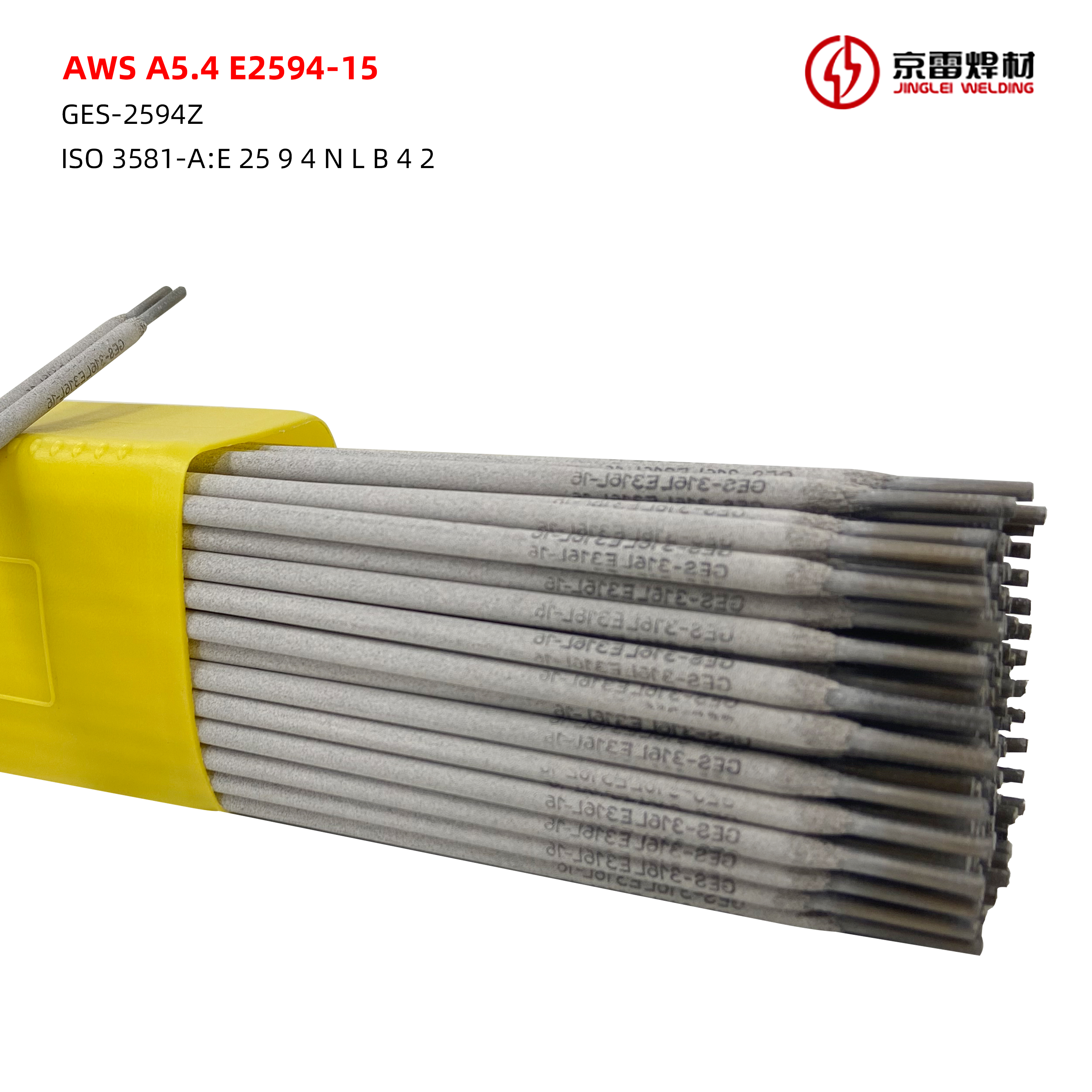

Stainless Steels Manual Electrode E2594-15 GXHY methanol dehydration tower electrode

THEKNOLOJI CHESE

Se lumelle lipotso

Tsoela pele ho u hlorisa

Arc ho hloka botsitso

Ho bopa ho sa kgahliseng

Spatter e feteletseng

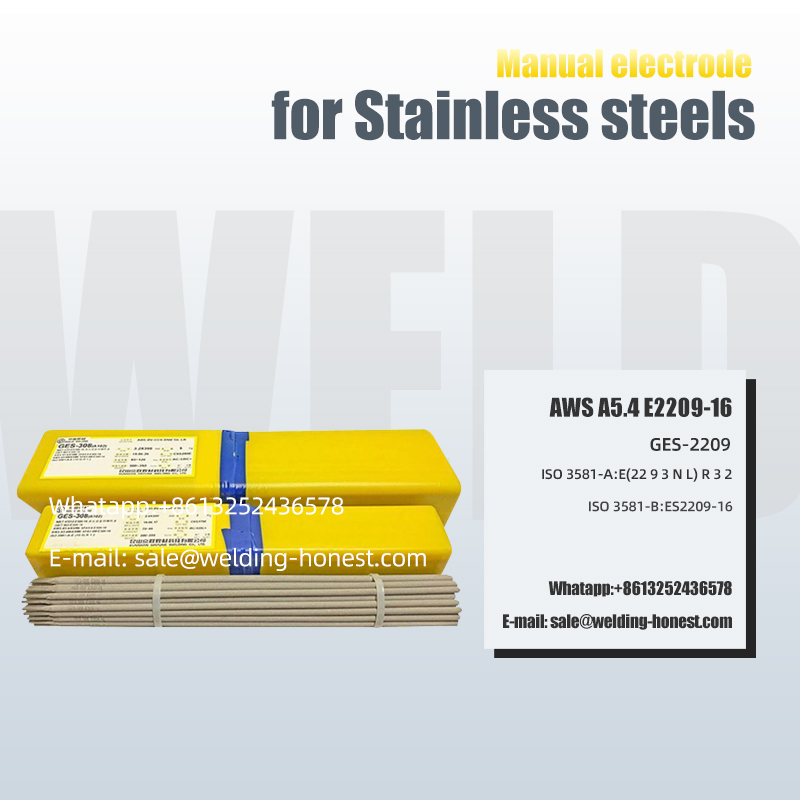

E loketse bakeng sa welding ea tšepe e sa hloekang ea duplex

e nang le 25% Cr, joalo ka 0022 crni7mo4n03cr25ni6mo3cu2n, joalo-joalo.

Elektrode ea letsoho e tlase ea hydrogen habeli ka tšepe e se nang tšepe, karolo e kholo ke 25.5Cr-10Ni-4Mo-0.25N

Ripple hantle

The weld metal ke austenitic le ferritic biphase

sebopeho, 'me index ea ho hanyetsa kutu ke PRE> 40

E na le matla a phahameng le khanyetso e ntle ea pitting le khatello ea maikutlo ea ho phatloha ho hoholo.

Theknoloji e ntle ea welding, arc e tsitsitseng, sebopeho se setle, ripple e tiea, ho phatloha ho honyenyane, ho tlosoa ha slag habonolo.

Slagging e bonolo

Parameter ea sehlahisoa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Tse ding |

| GB/T MELAO | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0,24 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | ||||

| GB/T MELAO | 918 | 22 | - | - | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Tšehetso ea fektheri

Sehlahisoa se loketse bakeng sa a

mefuta e mengata ea likopo

THEKNOLOJI CHESE

-

Lisebelisoa tsa ho cheselletsa likoloi tsa terene

Harbin motlakase liheke tse tharo tsa CMT

-

Koko ea jack-up ea CJ50

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Tse ding |

| GB/T MELAO | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0,24 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | ||||

| GB/T MELAO | 918 | 22 | - | - | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||