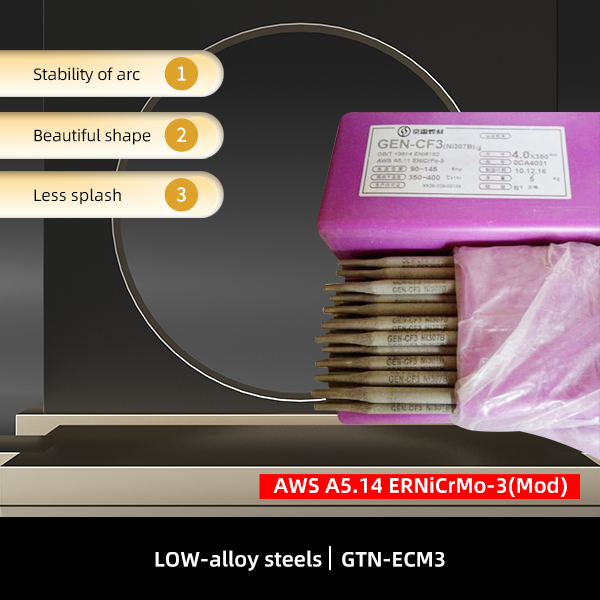

Nickel alloys Manual electrode ERNiCrMo-3(Mod) Soldering kgokelo

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Fe | Nb+Ti |

| MOHLALA BOHLOKOA | 0.01 | 0.12 | 0.44 | 21.7 | 62.7 | 8.25 | 0.003 | 0.003 | 0.9 | 3.41 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| MOHLALA BOHLOKOA | - | 765 | - | 38 | ||||

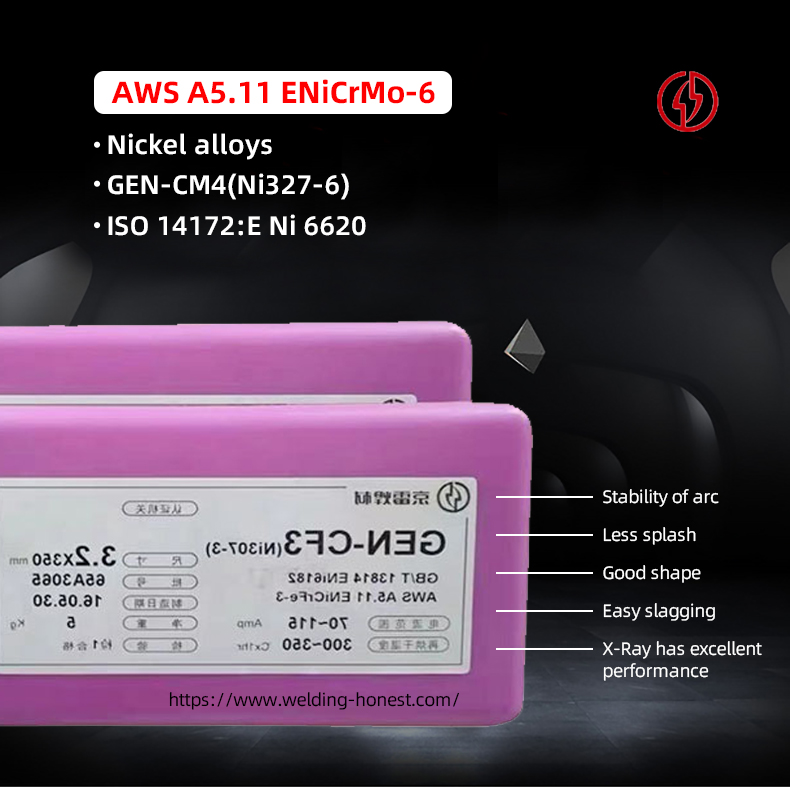

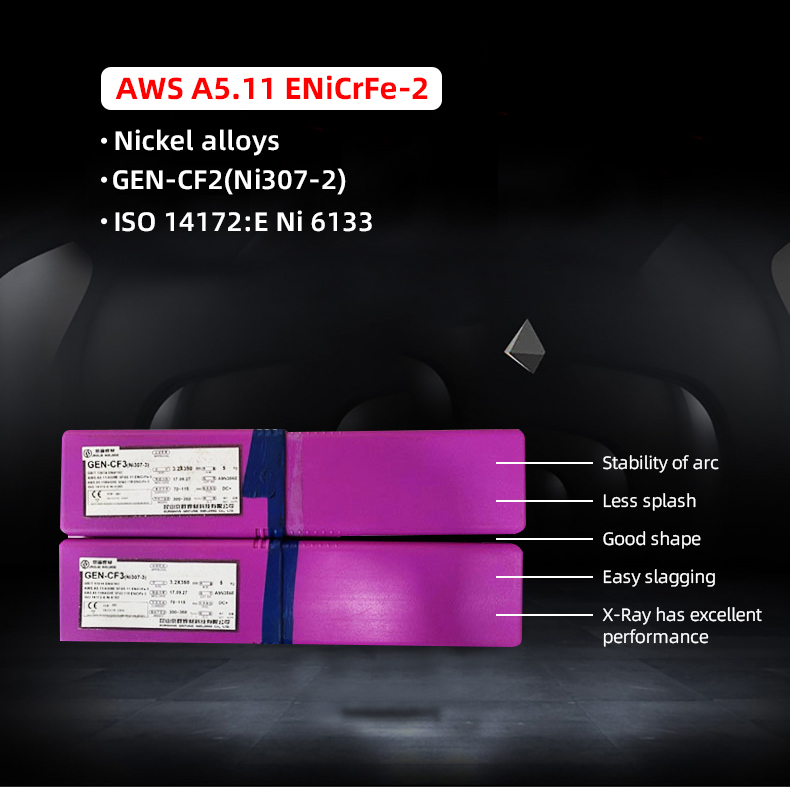

Sebopeho se seholo ke 61Ni-22Cr-9Mo-3.5Nb + Ta, e leng lisebelisoa tse sebelisoang ka ho fetisisa tsa nickel-chromium-molybdenum.

Ha terata ea ts'ireletso ea TIG e ts'oarella, seaparo se sireletsang se tla kenella ka morao ho letamo la weld, 'me se thehe lera le letenya le sireletsang ka mokhoa o ts'oanang ka pele le ka morao ea tselana ea weld, e le hore mahlakore ka bobeli a tsela ea weld a be teng. ha e na oxidized. Ho tjheseletsa ka lehlakoreng le le leng ho thehoa ka mahlakoreng ka bobeli, 'me slag ea welding e tla oa ka boeona ka mor'a hore sebaka sa weld se pholile.

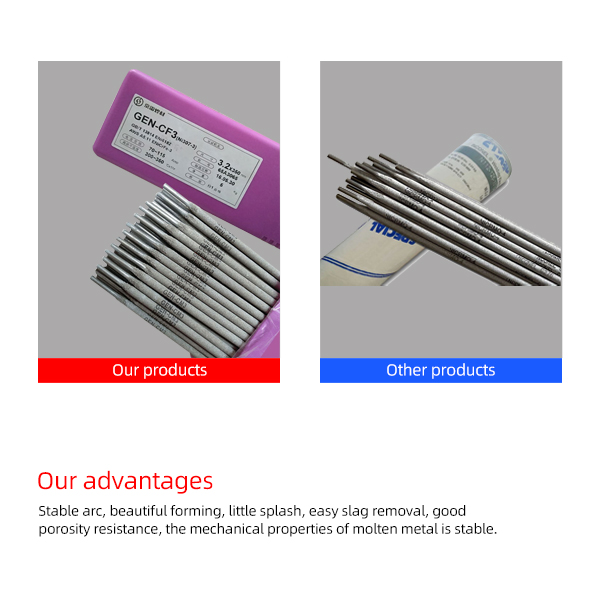

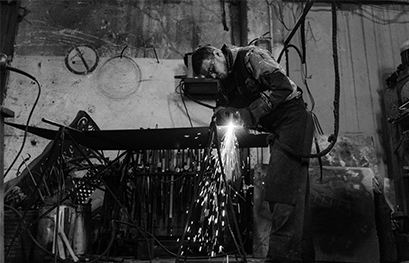

Mokhoa oa ho tjheseletsa oa terata o tšoana hantle le oa terata e tloaelehileng ea nickel e thehiloeng ho argon arc. Ho roala ho khethehileng ka holim'a metsi ha ho na phello e mpe ho weldability le thepa ea mechine. Arc e tsitsitse, sebopeho se setle, 'me ho phalla ha tšepe e chesang ho molemo.

-

Shaanxi Pucheng -50 ℃ propane spherical tank project

-

Libarele tse limilione tse 2.3 tsa SBM Fast4ward FPSO

-

Shandong Nuclear Power CV20

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Fe | Nb+Ti |

| MOHLALA BOHLOKOA | 0.01 | 0.12 | 0.44 | 21.7 | 62.7 | 8.25 | 0.003 | 0.003 | 0.9 | 3.41 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| MOHLALA BOHLOKOA | - | 765 | - | 38 | ||||