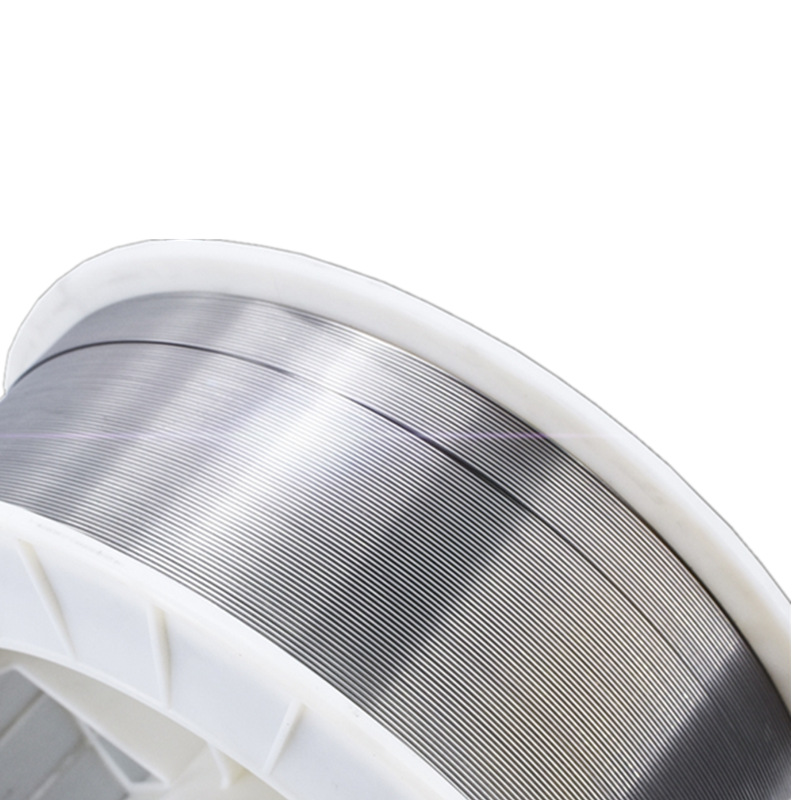

Li-alloys tsa Nickel TIG ERNiCrFe-7A Soldering jointing

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T MELAO | - | - | - | - | - | - | - | - | - | - |

| MOLAO OA MOLAO | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| MOHLALA BOHLOKOA | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | Phekolo ea mocheso | ||||||

| GB/T MELAO | - | - | - | - | - | ||||||

| MOLAO OA MOLAO | - | - | - | - | - | ||||||

| MOHLALA BOHLOKOA | - | 760 | 133/Mocheso oa kamore | 37 | 607°C*25h | ||||||

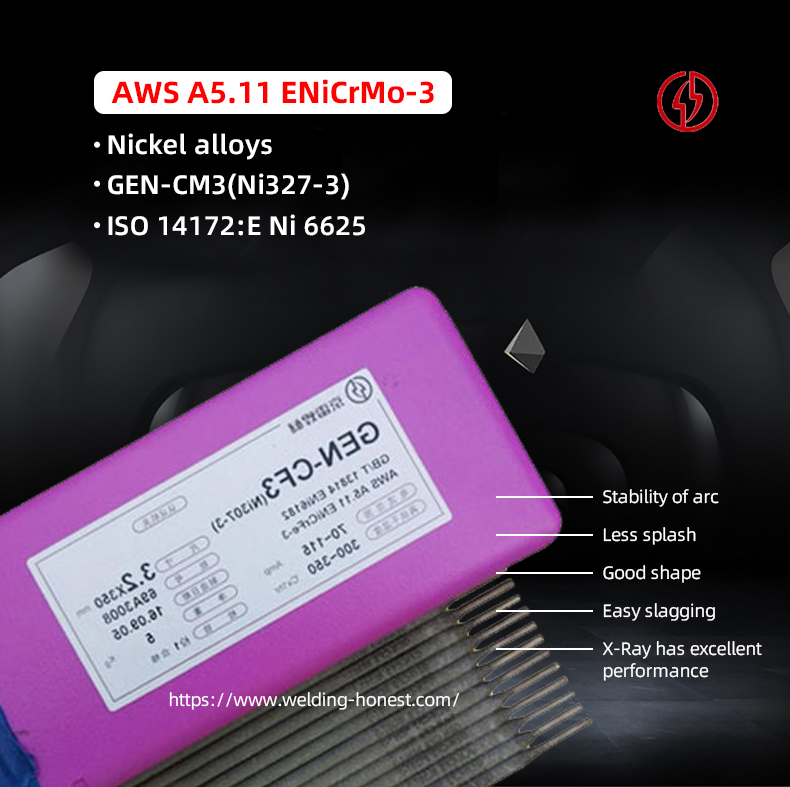

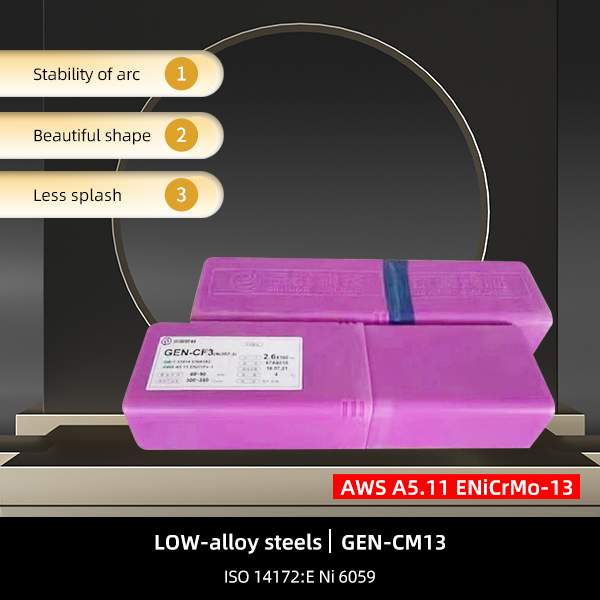

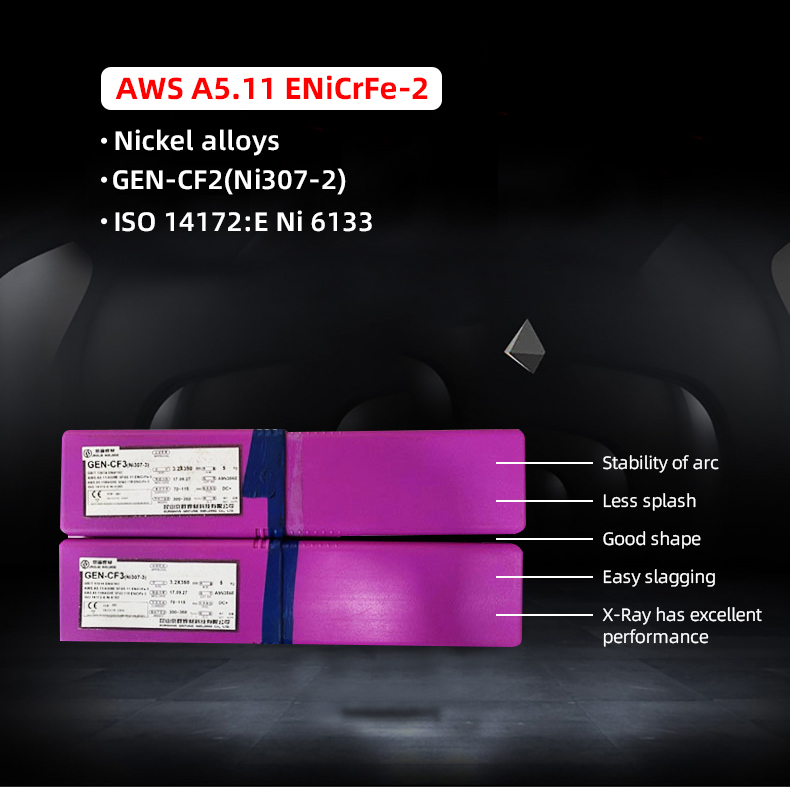

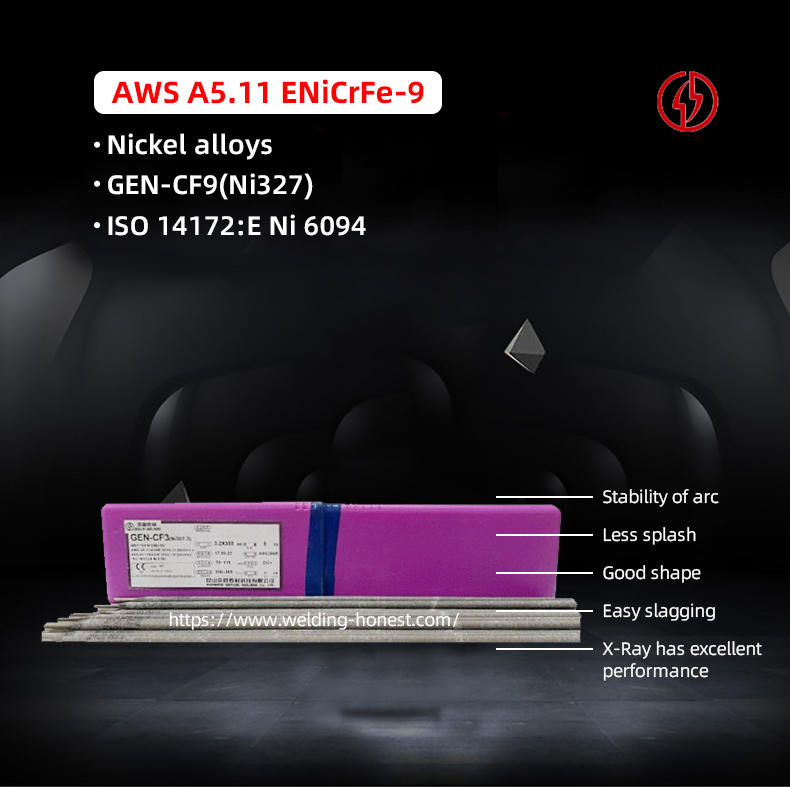

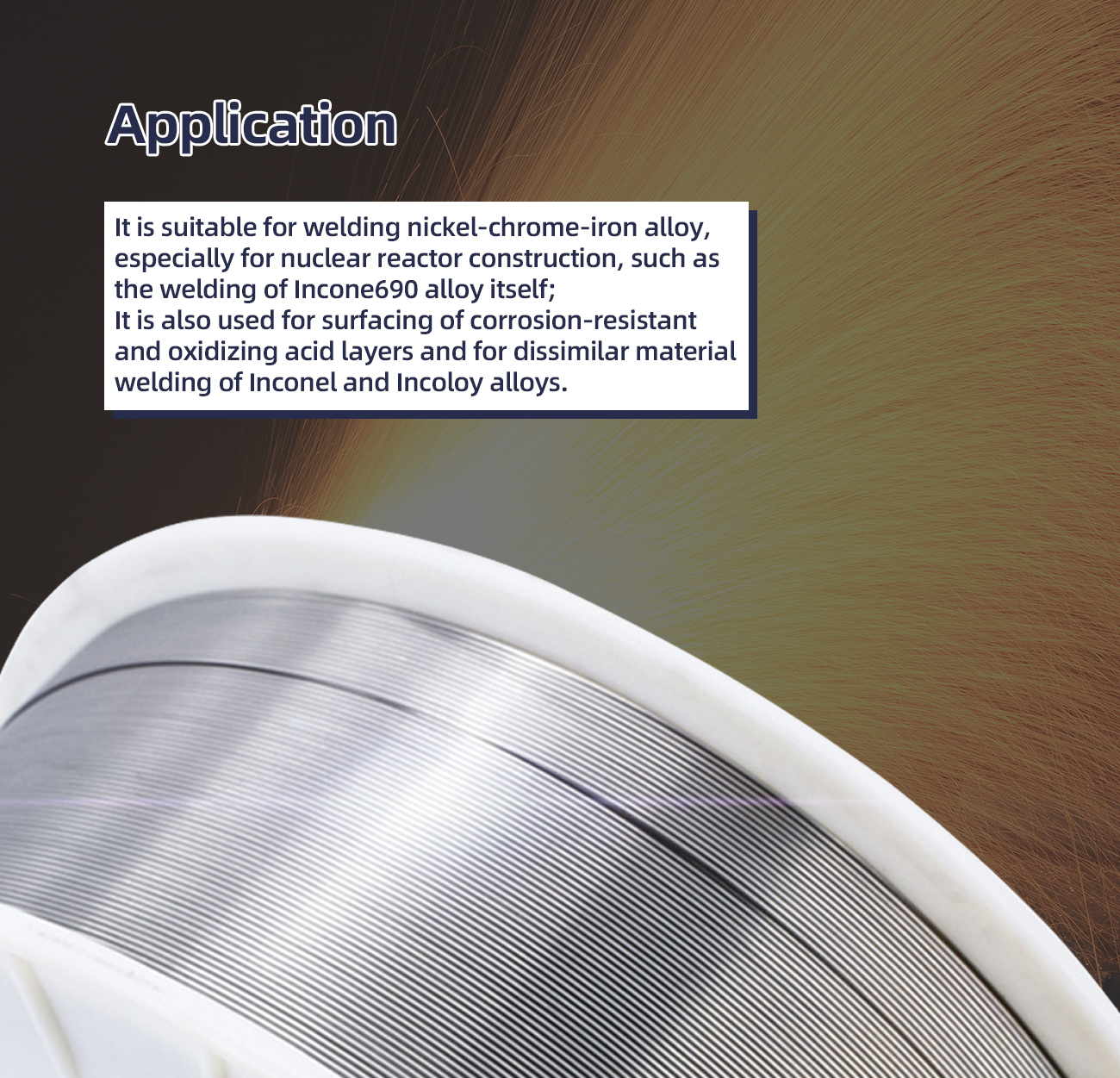

Nickel-chromium-iron nickel-base alloy gas wire welding, sebopeho sa lebitso ke 60%Ni-29%Cr-9%Fe-0.75%Nb.

Lisebelisoa tse ntle tsa mochini oa tšepe e qhibilihisitsoeng, haholo-holo ho hanyetsa ho phunyeha ha polasetiki e tlaase (DDC).

Likahare tse phahameng tsa Cr li e etsa hore e be le khanyetso e ntle ea khatello ea maikutlo ea ho senya tikolohong ea metsi a hloekileng tlas'a boemo ba mahlaseli. Arc e tsitsitseng, sebopeho se setle, phallo e ntle ea tšepe e qhibilihisitsoeng, e nang le ts'ebetso e ntle ea ts'ebetso ea welding.

-

Xinjiang Kela 2 Morero oa setsi sa kalafo se Bohareng

-

Lisebelisoa tsa ho cheselletsa bakeng sa ho khutsisa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T MELAO | - | - | - | - | - | - | - | - | - | - |

| MOLAO OA MOLAO | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| MOHLALA BOHLOKOA | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | Phekolo ea mocheso | ||||||

| GB/T MELAO | - | - | - | - | - | ||||||

| MOLAO OA MOLAO | - | - | - | - | - | ||||||

| MOHLALA BOHLOKOA | - | 760 | 133/Mocheso oa kamore | 37 | 607°C*25h | ||||||

Ngola molaetsa wa hao mona mme o re romele wona