Tora e sebelisoa bakeng sa distillation, tlhoekiso, monya, distillation le lisebelisoa tse ling tsa lik'hemik'hale, boholo ba lisebelisoa tsa tora li hloka ho ikopanya le acid, alkali, letsoai, li-solvents le mecha e meng e senyang, ka hona hoa hlokahala ho phunya sebaka se seholo sa lera le hanyetsanang le kutu. ka moqomong le dikarolong tsa ho tiisa. E le mokhoa o sebetsang oa ho okamela holim'a metsi, strip surfing e sebelisoa haholo ho tjheseletsa tora ea lisebelisoa tsa lik'hemik'hale.

Theknoloji ea setso ea li-electrode ke theknoloji e kaholimo ho metsi e nang le likarolo tse peli tse ka tlas'a metsi tse nang le lera la phetoho le lesela le sa khoneng ho bola, empa theknoloji ena e na le potoloho e telele ea tlhahiso le litšenyehelo tse phahameng tsa tlhahiso. E le ho rarolla bothata bona, JingQunCo e hlahisitse lisebelisoa tsa ho tjheseletsa ka holim'a lera le le leng (GDS-309LA welding strip, GXS-ED308L electroslag flux), e ka fihlelang phello ea ho phahama ha mekhahlelo e 'meli ka holim'a lera le le leng feela,' me e ka nolofatsa. mokgoa wa bokahodimo ho tloha bokahodimong ba meya e mmedi ho isa ho bokaholimo bo le bong.

Kenyelletso ea lisebelisoa tsa welding

1.Karolo ea lik'hemik'hale

| Rules/Lebitso | C | Si | Mn | P | S | Cr | Ni | Note |

| NB/T47018.5 EQ309LA | ≤0.030 | ≤1.00 | 0.5-2,5 | ≤0.025 | ≤0.015 | 21.0-23.0 | 9.0-12.0 | solder strip |

| GDS-309LA | 0.018 | 0.34 | 1.90 | 0.017 | 0.001 | 21.96 | 11.17 | solder strip |

| Rules/Lebitso | NB/T47018.5 FZ308-D | GDS-309LA+GXS-ED308L solder strip + Flux motsoako | |||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0.004 | 0.004 | 0.004 | 0.004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Hlokomela | tšepe e behiloeng | Sebaka sa ho tjheseletsa | Tlas'a bokaholimo ba 1mm | Tlas'a bokaholimo ba 2mm | Ka tlas'a bokaholimo ba 3mm |

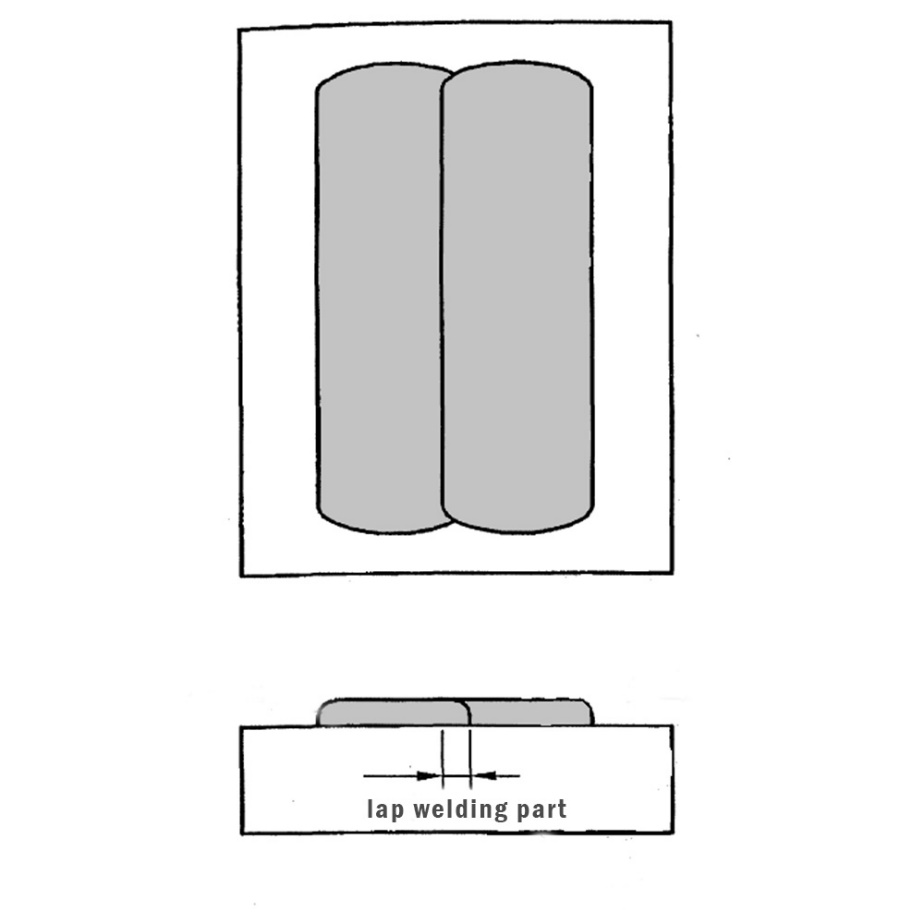

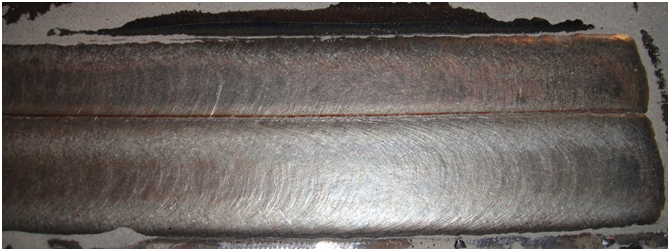

Ponahalo ea 2.Weld

E khothalelitsoeng li-welding parameters

| Tlhaloso(mm) | 0.5*60 |

| Motlakase(A) | 850-950 |

| Voltage(V) | 26-30 |

| WElding Speed(mm/min) | 150 |

| Lbolelele(mm) | 35-40 |

| Lap welding(mm/min) | 6-10 |

| Botenya ba flux spread(mm/min) | Abonyane 25 |

Weld pass botenya: hoo e ka bang 4.7mm

Weld bophara: hoo e ka bang 62.5mm

Ponahalo ea weld pass: sebopeho se setle, bokaholimo ba weld bo bataletse, phetoho ea lap e boreleli.

3.Bokhoni ba mechine

Likahare tsa Ferrite (boemo ba weld)

| Motsoako oa solder strip + Flux | GDS-309LA+GXS-ED308L |

| Boleng bo lekantsoeng | Likahare tsa ferrite li ka ba 7FN, 'me liperesente tsa ferrite li ka ba 8% |

| Boemo ba ho lekanya | Weld top |

Mokhoa oa teko: GB/T 1954-2008 "chromium-nickel austenitic stainless steel weld ferrite content measurement method"

Teko ea ho khumama:

as

620℃*20h

Liphetho tsa liteko: ho kobeha ka mahlakoreng, bophara ba indenter 4T (40mm), ho kobeha Angle 180 ° ntle le ho phatloha.

Teko ea kutu ea intergranular

Joalo ka welded

620℃*20h

Mokhoa oa teko: GB/T 4334-2020 Mokhoa oa E

Tharollo ea teko: koporo - sulfate ea koporo -16% sulfuric acid

Liphetho tsa liteko: Ha ho na "intergranular corrosion crack".

Micro metallography ea lera le holimo

Joalo ka welded

Joalo ka welded

620 ℃ * 20h kalafo mocheso

620 ℃ * 20h kalafo mocheso

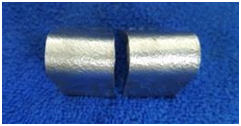

Kopo ea boenjiniere

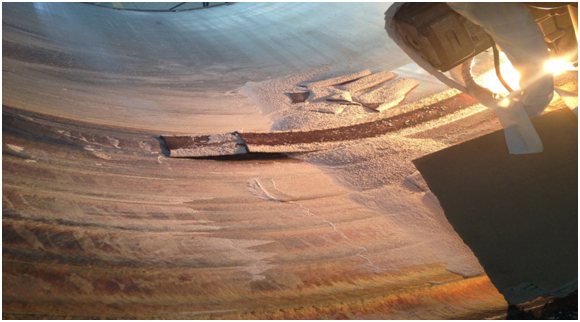

Ts'ebetso ea tlhahlobo ea ts'ebetso ea 1.Customer welding

2.Mohaho oa sebaka sa bareki

Kamora lilemo tsa lipatlisiso le nts'etsopele, ts'ebetso ea lisebelisoa tsa welding ea Jingqun single-layer electroslag e tsitsitse ebile e ka tšeptjoa, e na le likatleho tse ngata tsa kopo ea boenjiniere.

Amohela bareki ho buisana le ho khetha!

Lintlha tse ling eketsa whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Nako ea poso: Nov-04-2022