Nakong ea ts'ebetso ea hardfacing, mapetsong hangata a baka mathata a kang ho sebetsa hape le ho khutla ha bareki. Sefate sa sefahleho se thata se fapane le tjheseletsa e akaretsang ea sebopeho, 'me kahlolo le tataiso ea mapetsong le tsona li fapane haholo. Sengoliloeng sena se sekaseka le ho bua ka ponahalo e atileng ea mapetsong ts'ebetsong ea ho sesa ha sefahleho se thata.

1. Boikemisetso ba mapetsong

Hona joale, ka hare ho naha esita le linaheng tse ling, ha ho na mokhoa o akaretsang oa ho phatloha ho bakoang ke ho apara ka thata holim'a metsi. Lebaka le ka sehloohong ke hore ho na le mefuta e mengata haholo ea maemo a ho sebetsa bakeng sa lihlahisoa tsa ho roala ka thata holim'a metsi, 'me ho thata ho hlalosa mekhoa e fapaneng e sebetsang ea kahlolo ea crack tlas'a maemo. Leha ho le joalo, ho ea ka phihlelo ea tšebeliso ea lisebelisoa tsa ho cheseletsa tse sa sebetsaneng ka thata libakeng tse sa tšoaneng, likarolo tse 'maloa tsa crack li ka hlophisoa ka mokhoa o batlang o lekana, hammoho le litekanyetso tsa ho amoheloa liindastering tse fapaneng:

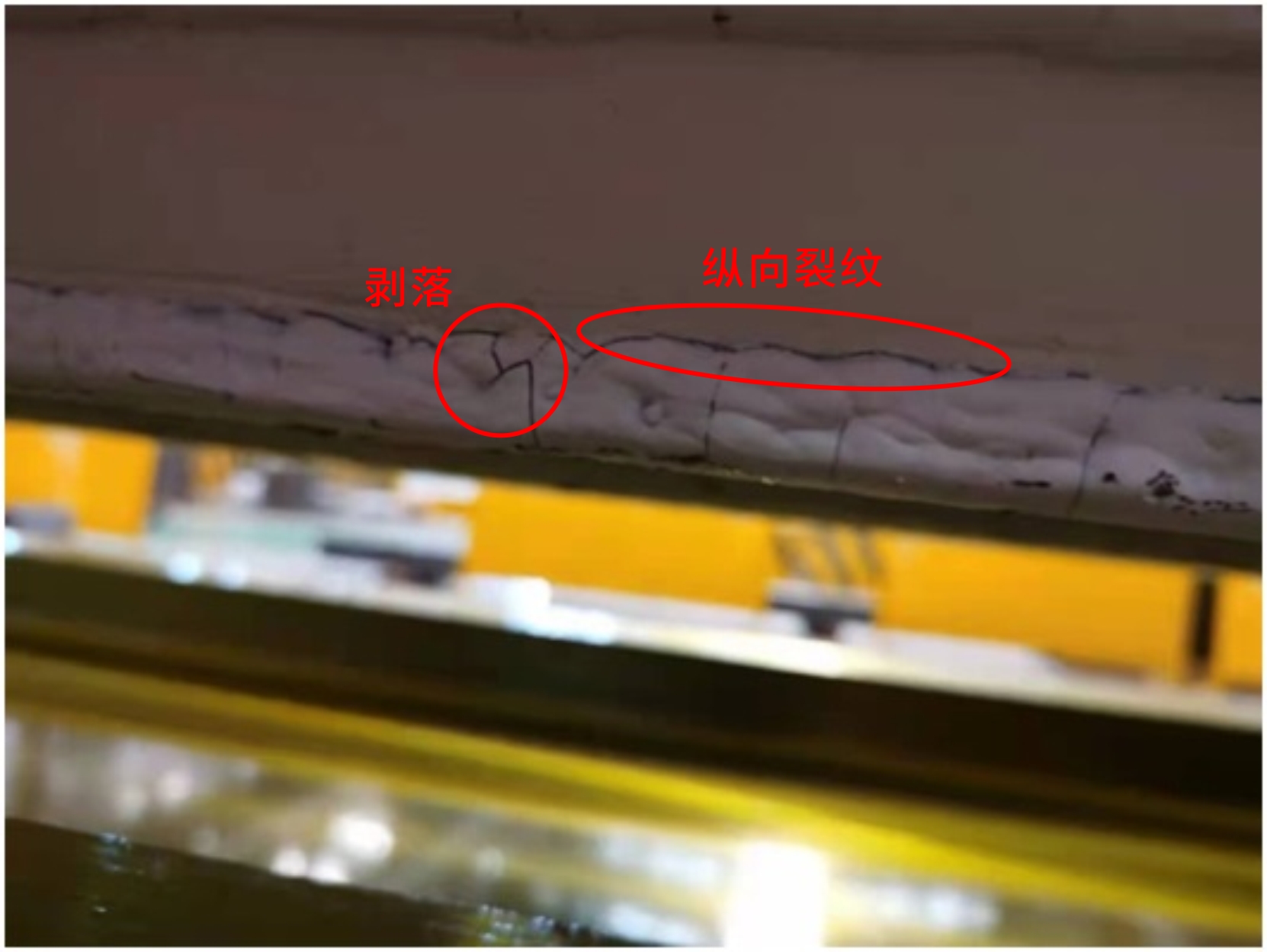

1. Taelo ea ho petsoha e bapa le sefaha se cheselletsang (longitudinal crack), lepetso le sa khaotseng, le phunyeletsang ho ea tšepeng ea motheo, ho petsoha.

Ha feela e 'ngoe ea mekhahlelo e boletsoeng ka holimo e fihletsoe, ho na le kotsi ea hore lera lohle le ka holimo le tla oa. Ha e le hantle, ho sa tsotellehe hore na kopo ea sehlahisoa ke efe, ha e amohelehe 'me e ka sebelisoa hape le ho rekisoa hape.

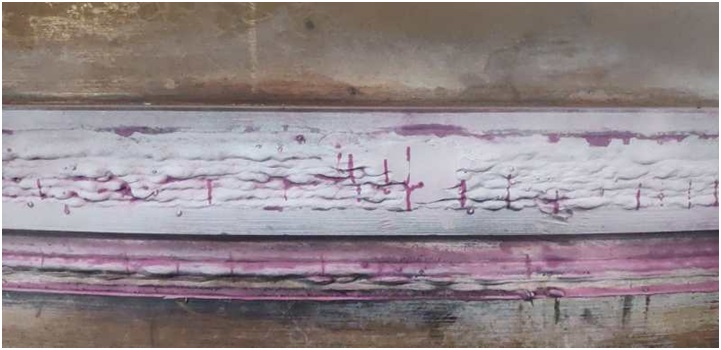

2. Ho na le mapetsong a mosehla feela le ho se tsoele pele

Bakeng sa lisebelisoa tse amanang le lisebelisoa tse tiileng tse kang ore, sandstone, le merafo ea mashala, ho thatafala ho tlameha ho ba holimo (HRC 60 kapa ho feta), 'me lisebelisoa tsa ho cheseletsa tse nang le chromium tse ngata hangata li sebelisoa bakeng sa ho cheselletsa holim'a metsi. Likristale tsa chromium carbide tse entsoeng ka bead ea weld li tla hlahisoa ka lebaka la ho lokolloa ha khatello ea maikutlo. Mapetso a amoheleha ha feela tataiso ea crack e le perpendicular ho weld bead (transverse) 'me e sa tsoele pele. Leha ho le joalo, palo ea mapetsong a ntse a tla sebelisoa e le sesupo sa ho bapisa melemo le bofokoli ba lisebelisoa tsa welding kapa lits'ebetso tse holim'a metsi.

3. Ha ho crack weld bead

Bakeng sa li-workpieces tse kang li-flanges, li-valve, le liphaephe, moo lintho tse ka sehloohong tsa ho kopana le likhase le metsi, litlhoko tsa mapetsong a bead ea weld li hlokolosi haholoanyane, 'me ka kakaretso ho hlokahala hore ponahalo ea sefaha sa weld ha ea lokela ho ba le mapetsong.

Mapetsong a manyane holim'a lisebelisoa tse kang li-flange le li-valve li hloka ho lokisoa kapa ho etsoa bocha.

Sebelisa lisebelisoa tse khethehileng tsa welding tsa k'hamphani ea rona ea GFH-D507Mo bakeng sa ho phahama, ha ho mapetsong holim'a metsi.

2. Lisosa tse ka sehloohong tsa mapetsong a ka holimo a thata a sa sebetseng

Ho na le mabaka a mangata a bakang mapetsong. Bakeng sa tjheseletsa e thibang holim'a holim'a sefahleho se thata, e ka aroloa ka mapetsong a chesang a ka fumanoang ka mor'a hore ho fete pele kapa la bobeli, le mapetsong a batang a hlahang ka mor'a ho feta ha bobeli kapa esita le ka mor'a ho tjheseletsa hohle.

Hot crack:

Nakong ea ts'ebetso ea ho tjheseletsa, tšepe e ka har'a seam seam le sebaka se amehileng ke mocheso se pholile ho ea sebakeng sa mocheso o phahameng haufi le mohala oa solidus ho hlahisa mapetsong.

Leqhoa le batang:

Mapetso a hlahisoang ka mocheso o ka tlase ho solidus (hoo e batlang e le mocheso oa phetoho ea martensitic ea tšepe) haholo-holo a hlaha ka litšepe tse mahareng tsa k'habone le litšepe tse matla tse tlase tsa alloy le litšepe tse mahareng tsa alloy.

Joalokaha lebitso lena le bontša, lihlahisoa tse thata tsa holim'a metsi li tsejoa ka ho thatafala ha tsona holimo. Leha ho le joalo, ho lelekisa ho thatafala ha mechini ho boetse ho fella ka ho fokotseha ha polasetiki, ke hore, ho eketseha ha brittleness. Ha re bua ka kakaretso, ho phahama ka holimo ho HRC60 ha ho ele hloko mapetsong a mocheso a hlahisoang nakong ea ho cheselletsa. Leha ho le joalo, ka thata holim'a tjheseletsa ka thata pakeng tsa HRC40-60, haeba ho na le tlhokahalo bakeng sa mapetsong, The intergranular mapetsong a tshebetso tjheseletsa kapa liquefaction le mapetsong a multilateral a bakoang ke e holimo weld sefaha ho ea sebakeng mocheso-amehile tsa tjheseletsa tlaase. li-bead li thata haholo.

Esita le haeba bothata ba mapetsong a chesang bo laoloa hantle, tšokelo ea mapetsong a batang e ntse e tla tobana le eona ka mor'a ho tjheseletsa ka holim'a metsi, haholo-holo thepa e brittle e kang hard surface weld bead, e khonang ho mamella mapetsong a batang. Ho petsoha ho matla hangata ho bakoa ke mapetsong a batang

3. Lintlha tsa bohlokoa tse amang mapetsong a sa sebetseng holim'a libaka tse thata le maano a ho qoba mapetsong

Lintlha tsa bohlokoa tse ka hlahlojoang ha mapetsong a hlaha ts'ebetsong ea ho roala ka thata holim'a metsi ke tse latelang, 'me maqheka a lumellanang a hlahisoa bakeng sa ntlha e' ngoe le e 'ngoe ho fokotsa kotsi ea mapetsong:

1. Thepa ea motheo

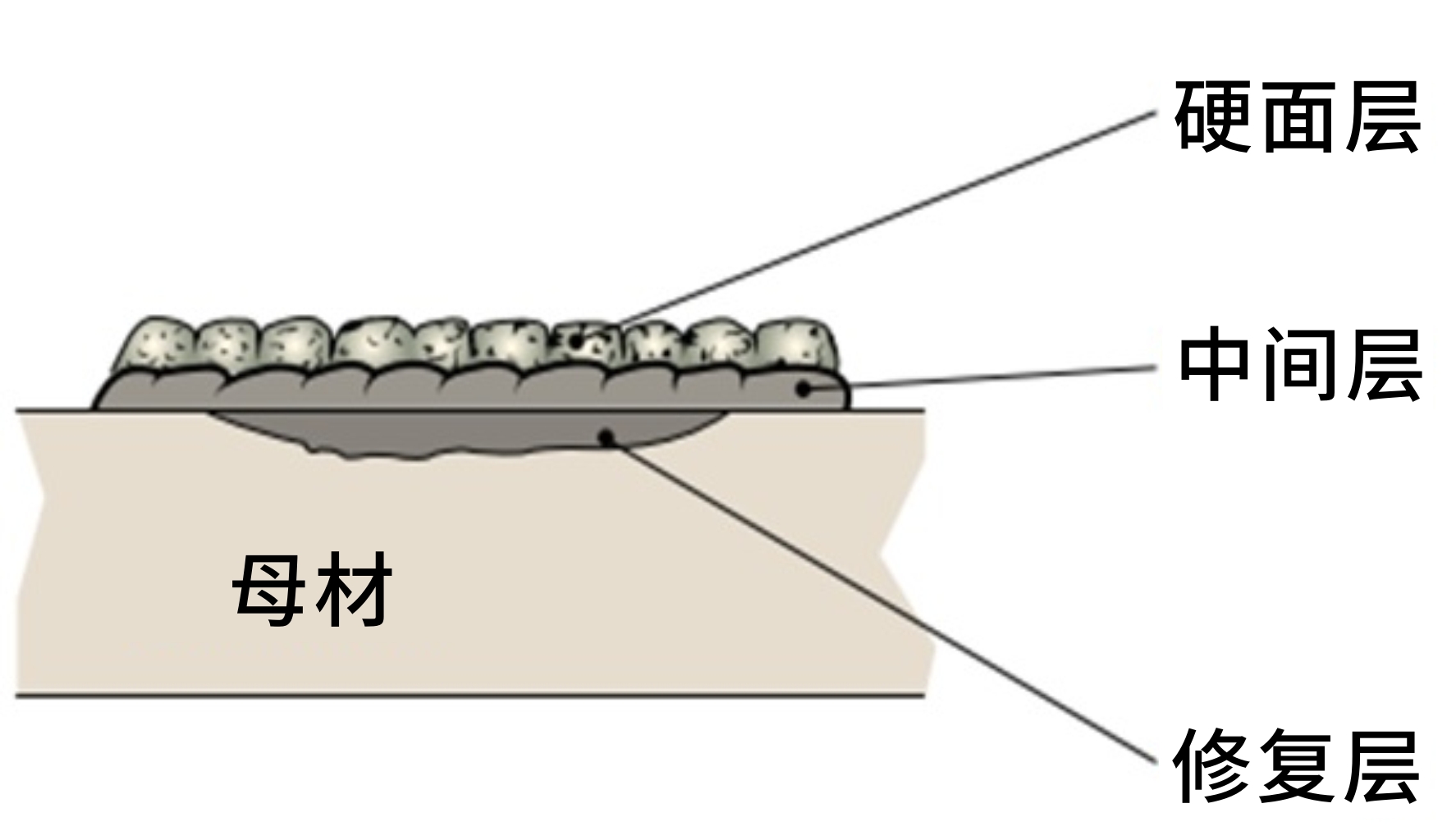

Tšusumetso ea tšepe ea motheo holim'a holim'a metsi a thata a sa sebetseng ke ea bohlokoa haholo, haholo-holo bakeng sa lisebelisoa tse nang le likarolo tse ka tlaase ho tse peli tsa li-welding tse holimo. Sebopeho sa tšepe ea motheo se ama ka ho toba thepa ea weld bead. Khetho ea thepa ke lintlha tse lokelang ho eloa hloko pele o qala mosebetsi. Mohlala, haeba mochini oa ho sebetsa oa valve o nang le boima ba 'mele oa HRC30 o ka holim'a thepa ea tšepe e entsoeng ka tšepe, ho kgothaletswa ho sebelisa thepa ea welding e nang le boima bo tlase hanyane, kapa ho eketsa lera la tšepe e sa hloekang bohareng, qoba litaba tsa khabone ka har'a thepa ea motheo hore li se ke tsa eketsa kotsi ea mapetsong a lifaha tsa weld.

Eketsa lera le bohareng holim'a lisebelisoa tsa motheo ho fokotsa kotsi ea ho senya

2. Lisebelisoa tsa ho cheselletsa

Bakeng sa ts'ebetso e sa hlokeng mapetsong, lisebelisoa tsa welding tse phahameng tsa carbon le high-chromium ha lia lokela. E kgothaletswa ho sebelisa martensitic tsamaiso tjheseletsa consumables, tse kang rona GFH-58. E ka tjheseletsa sefaha se senang mapheo ha boima bo le hodimo ho HRC58~60, haholoholo se loketse dibaka tsa mosebetsi tse sa rerwang tse hohlang haholo ke mobu le majwe.

3. Ho kenya mocheso

Kaho ea setšeng e tloaetse ho sebelisa matla a holimo le matla a motlakase ka lebaka la ho toboketsa ts'ebetso, empa ho fokotsa hona joale le motlakase ka mokhoa o itekanetseng le hona ho ka fokotsa ho hlaha ha mapetsong a mocheso.

4. Taolo ea mocheso

Multi-layer le multi-pass hardfacing welding e ka nkoa e le mokhoa oa ho futhumatsa ho tsoelang pele, ho pholisa le ho futhumatsa hape bakeng sa ho feta ka 'ngoe, kahoo taolo ea mocheso e bohlokoa haholo, ho tloha ho futhumatsa pele ho tjheseletsa ho fetisa mocheso nakong ea Taolo ea holim'a metsi, esita le mokhoa oa ho pholisa ka mor'a welding, hloka tlhokomelo e kholo.

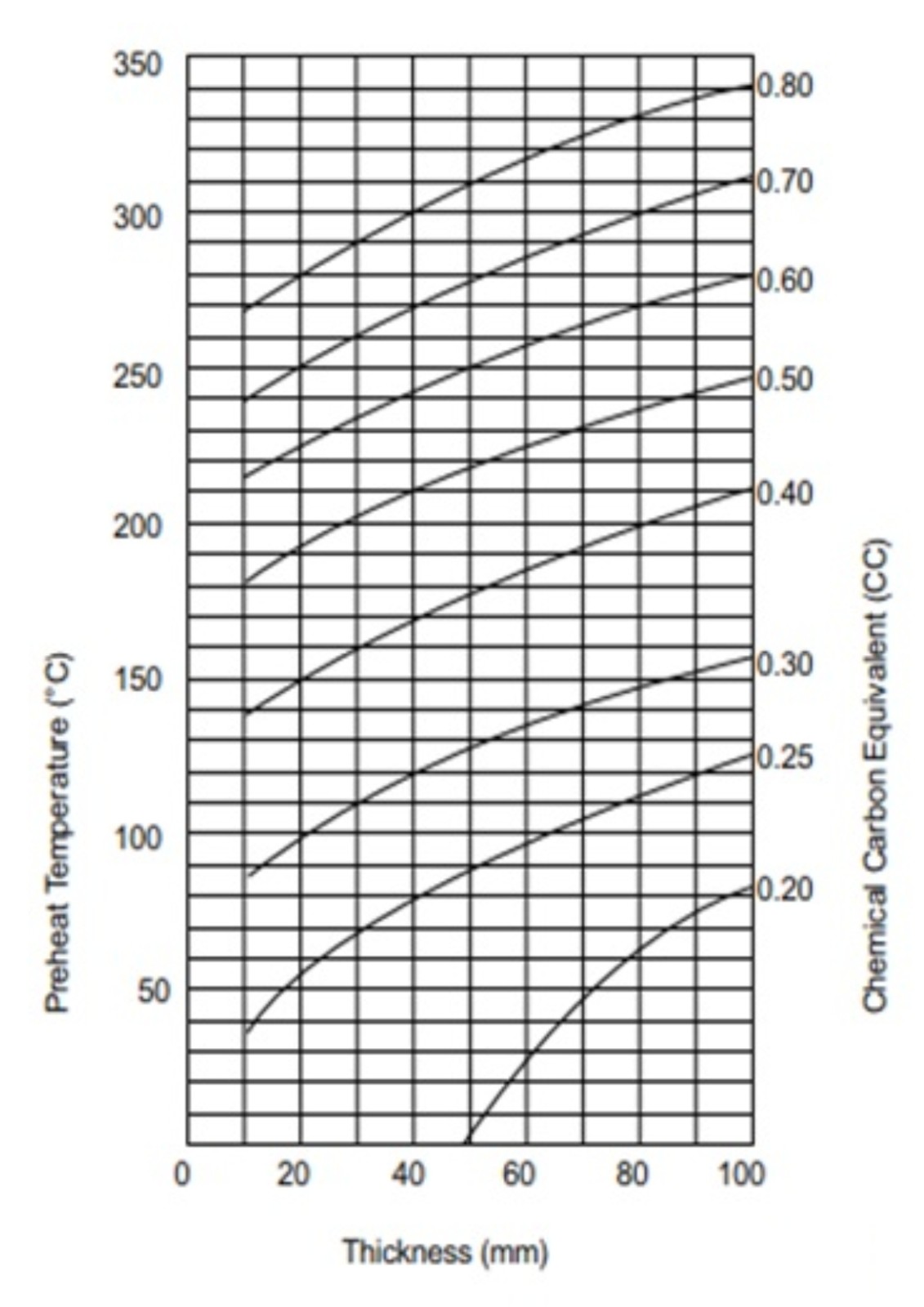

Mocheso oa preheating le pina oa welding ea holim'a metsi o amana haholo le khabone ea substrate. Substrate mona e kenyelletsa thepa ea motheo kapa lera le bohareng, le tlase ea sebaka se thata. Ha re bua ka kakaretso, ka lebaka la carbon content ea tšepe e thata e kentsoeng Haeba litaba li le holimo, ho kgothaletswa ho boloka mocheso wa tsela ka holimo ho likhato tse 200. Leha ho le joalo, ts'ebetsong ea 'nete, ka lebaka la bolelele bo bolelele ba sefaha se cheselletsang, karolo e ka pele ea sefaha sa weld e se e pholile qetellong ea pase e le' ngoe, 'me pase ea bobeli e tla hlahisa mapetsong habonolo sebakeng se anngoeng ke mocheso oa substrate. . Ka hona, ho ba sieo ha thepa e nepahetseng ho boloka mocheso oa kanale kapa preheat pele ho tjheseletsa, ho kgothaletswa ho sebetsa ka likarolo tse ngata, li-welds tse khutšoane, le li-welding tse tsoelang pele sebakeng se le seng ho boloka mocheso oa kanale.

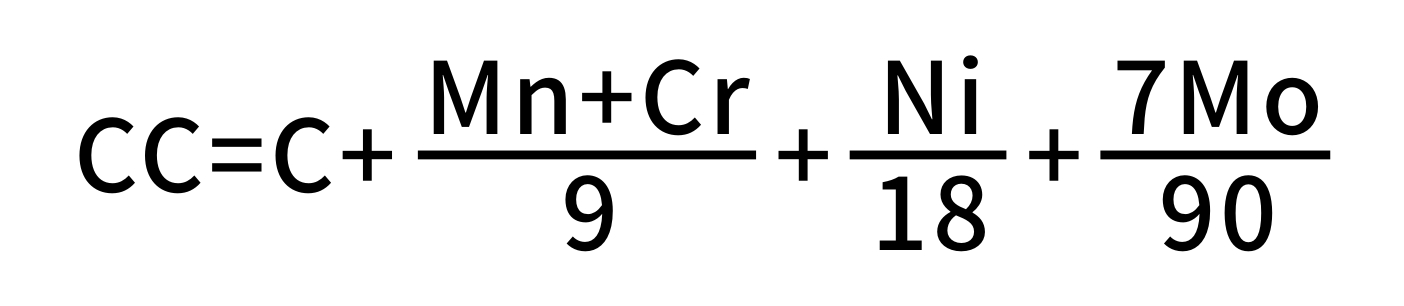

Kamano pakeng tsa carbon content le preheating mocheso

Ho pholisa butle ka mor'a ho phahama le hona ke mohato o mahlonoko empa hangata o hlokomolohuoang, haholo bakeng sa lisebelisoa tse kholo tsa mosebetsi. Ka linako tse ling ha ho bonolo ho ba le lisebelisoa tse loketseng ho fana ka maemo a liehang a ho pholile. Haeba ho hlile ho se na mokhoa oa ho rarolla boemo bona, re ka e khothaletsa feela ho e sebelisa hape Mokhoa oa ts'ebetso e arohaneng, kapa ho qoba ho tjheseletsa ha mocheso ha mocheso o le tlase, ho fokotsa kotsi ea mapetsong a batang.

Tse nne. Qetello

Ho ntse ho e-na le liphapang tse ngata tsa baetsi ba batho ka bomong litlhoko tsa hardfacing bakeng sa mapetsong a lisebelisoa tse sebetsang. Sengoliloeng sena se etsa feela puisano e thata ho latela boiphihlelo bo fokolang. Letoto la lisebelisoa tsa welding tsa k'hamphani ea rona li na le lihlahisoa tse tsamaellanang tseo bareki ba ka li khethang bakeng sa boima le lits'ebetso tse fapaneng. Rea u amohela ho buisana le khoebo seterekeng ka seng.

Tšebeliso ea fektheri ea boto e sa tsitsang

| Ntho | Sireletsa khase | boholo | Ka sehloohong | HRC | Ho sebelisa |

| GFH-61-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Joalo: 0.6 Mohl:1.2 Kr:28.0 | 61 | E loketse mabili a ho sila, li-mixer tsa samente, li-bulldozer, joalo-joalo. |

| GFH-65-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Lik:22,5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | E loketse bakeng sa li-fan tsa mocheso o phahameng oa mocheso, lisebelisoa tsa ho fepa sebōpi, joalo-joalo. |

| GFH-70-O | Tshireletso | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0,3 | 68 | E sebetsa ho rolara ea mashala, bofubelu ba ghost, lisebelisoa tsa ho amohela, ho phatloha sekoaelo sa mashala, grinder, joalo-joalo. |

Kopo indastering ea samente

| Ntho | Sireletsa khase | boholo | Ka sehloohong | HRC | Ho sebelisa |

| GFH-61-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Joalo: 0.6 Mohl:1.2 Kr:28.0 | 61 | E loketse ho sila li-roller tsa majoe, li-mixer tsa samente, joalo-joalo |

| GFH-65-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Lik:22,5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | E loketse bakeng sa li-fan tsa mocheso o phahameng oa mocheso, lisebelisoa tsa ho fepa sebōpi, joalo-joalo. |

| GFH-70-O | Tshireletso | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0,3 | 68 | E loketse ho sila li-roller tsa majoe, meno a moea, ho amohela meno, li-grinders, joalo-joalo. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 Joalo: 0.87 Mohl:2,6 Mo:0.53 | 36 | E sebetsa ho likarolo tsa tšepe ho isa ho tšepe tse kang mabili a moqhaka le li-axle |

| GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Sie:0.42 Mohl:2,1 Kr:2.8 Mo:0.43 | 38 | E sebetsa ho likarolo tsa tšepe ho isa ho tšepe tse kang mabili a moqhaka le li-axle |

Tšebeliso ea Semela sa tšepe

| Ntho | Sireletsa khase | boholo | Ka sehloohong | HRC | Ho sebelisa |

| GFH-61-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Joalo: 0.6 Mohl:1.2 Kr:28.0 | 61 | E loketse liballo tsa sebōpi sa semela sa sintering, meno a ghost, lipoleiti tse sa keneng, joalo-joalo. |

| GFH-65-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Lik:22,5 Mo:3.2 V:1.1 W:1,368 Nb:3.5 | 65 | |

| GFH-70-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Kr:30.0 B:0,3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 Joalo: 0.65 Mohl:1.1 Kr:13.2 | 52 | E loketse bakeng sa li-casting rolls, rolls rolls, steering rolls, joalo-joalo limela tse tsoelang pele tsa ho lahlela le limela tse chesang tse chesang. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Sie:0.42 Mohl:1.1 Lik:13,4 Mo:1.1 V:0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C:0,25 Sie:0.45 Mohl:2.0 Kr:5.8 Mo:0.8 V:0.3 W:0.6 | 51 | Lisebelisoa tsa ho roala li-anti-adhesive, tse loketseng meqolo e tsamaisang fektheri ea tšepe, li-roll le likarolo tsa ho roala lipakeng tsa tšepe. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C:0.36 Joalo: 0.64 Mohl:2.0 Ntlhe:2.9 Kr:6.2 Mo:1.35 V:0.49 | 52 |

Kopo ea morafo

| Ntho | Sireletsa khase | boholo | Ka sehloohong | HRC | Ho sebelisa |

| GFH-61-0 | Tshireletso | 1.6 2.8 3.2 | C:5.0 Joalo: 0.6 Mohl:1.2 Kr:28.0 | 61 | E sebetsa ho li-excavators, lihlooho tsa litsela, likhetho, joalo-joalo. |

| GFH-58 | CO2 | 1.6 2.4 | C:0.5 Joalo: 0.5 Mohl: 0,95 Ke:0.03 Kr:5.8 Mo:0.6 | 58 | E loketse bakeng sa ho cheselletsa ka holim'a metsi ka lehlakoreng la sejana sa ho fana ka majoe |

| GFH-45 | CO2 | 1.6 2.4 | C:2.2 Joalo:1.7 Mohl:0.9 Kr:11.0 Mo:0.46 | 46 | E loketse ho roala likarolo pakeng tsa litšepe |

Sesebelisoa sa valve

| Ntho | Sireletsa khase | boholo | Ka sehloohong | HRC | Ho sebelisa |

| GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0,45 Mohl:0,4 Ke:0.1 Lik:13 Mo:0.01 | 40 | E loketse bakeng sa ho tjheseletsa ka holim'a holim'a holim'a li-valve sealing surface |

| GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0,45 Mohl:0,4 Ke:0.1 Lik:13 Mo:0.01 | 58 | E loketse ho tjheseletsa ha li-valve tse nang le corrosiveness e phahameng |

| GFH-D547Mo | Melamu ea matsoho | 2.6 3.2 4.0 5.0 | C:0.05 Mohl:1,4 Sie:5.2 P:0.027 S:0.007 Ntlhe:8.1 Lik:16.1 Mo:3.8 Nb:0.61 | 46 | E loketse mocheso o phahameng, li-valve tse phahameng tsa khatello e holimo |

More information send to E-mail: export@welding-honest.com

Nako ea poso: Dec-26-2022