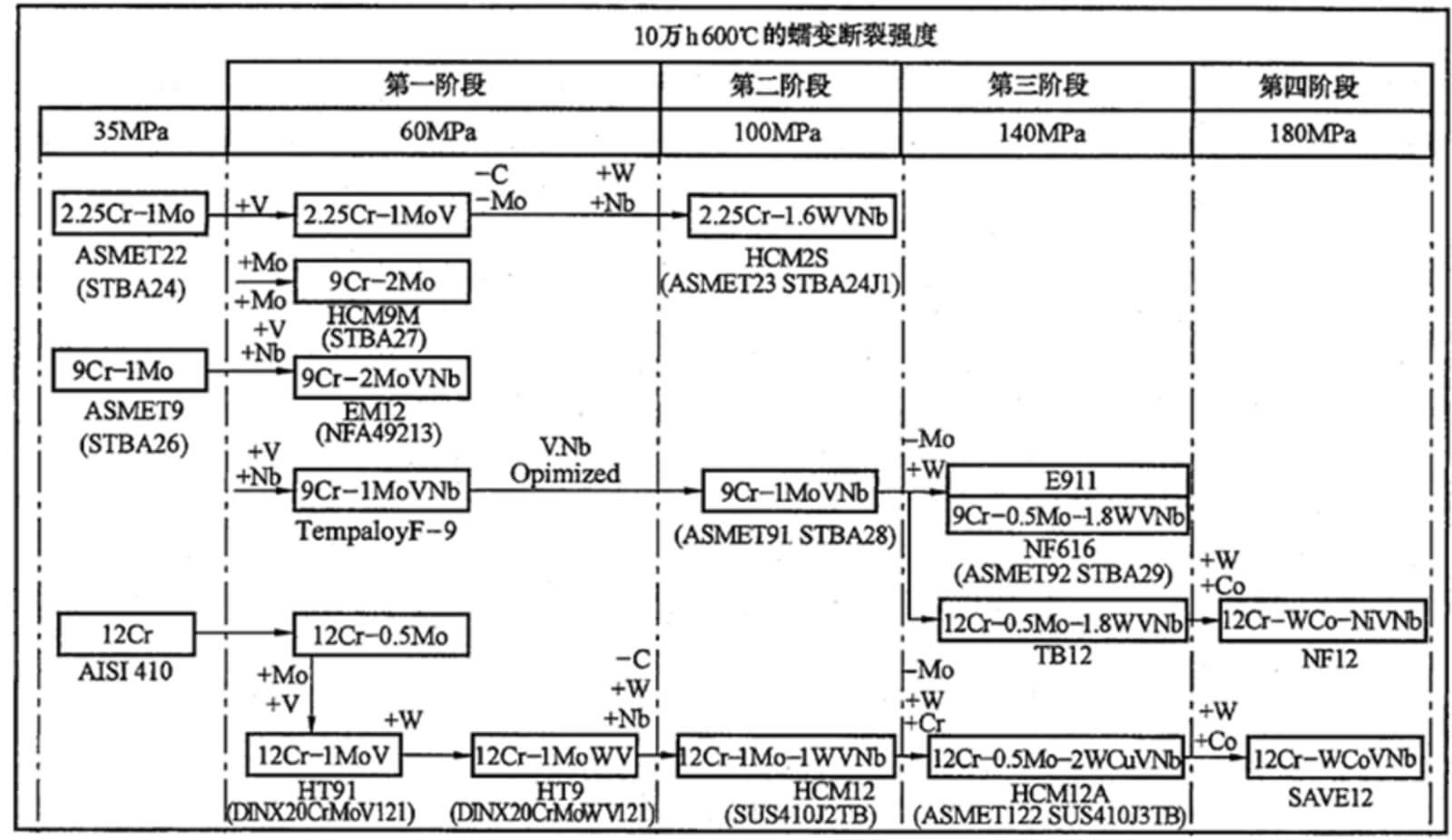

Nts'etsopele ea tšepe ea ferritic e thibelang mocheso

Eketsa Cr-1.25Cr ho isa ho 12Cr

Kenya V, Nb, Mo, W, Co, joalo-joalo.

Mokhoa oa nts'etsopele oa tšepe e sa keneleng mocheso oa ferritic

Hlokomela:

Ho ea ka mekhoa ea machaba, litšepe tse bitsoang pearlite, bainite, le martensitic tse thibelang mocheso ka har'a li-boiler le lipeipi li bitsoa "litšepe tsa ferritic tse thibelang mocheso".

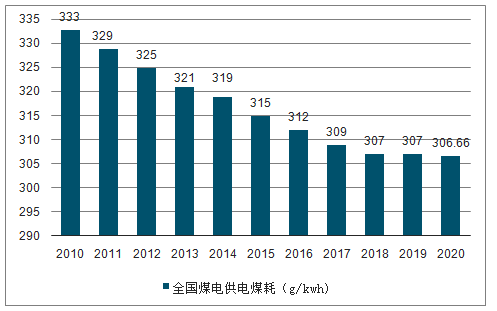

Ka tokiso ea sebopeho sa matla a naha ea heso le ho ntlafatsa kaho ea phepelo ea motlakase, matla a maholo, a hloekileng, a se nang tikoloho, a nang le matla a maholo le a holimo-limo a se a rena. Ka ho eketsa litekanyetso tsa mouoane (khatello le mocheso), e ka ntlafatsa katleho ea mocheso oa yuniti ka katleho, ea fokotsa tšebeliso ea mashala le ho fokotsa tlhahiso ea CO2. Hajoale, mokhoa o ka sehloohong oa ho ntlafatsa ts'ebetso ea li-unit tsa motlakase oa mocheso ke ho ntlafatsa li-parameter tsa mouoane le ho nts'etsapele li-unit tsa supercritical (SC) le ultra-supercritical (USC). Hajoale, ho na le likarolo tse fetang limilione tse 100 tsa li-kilowatt tsa Ultra-supercritical (USC) tse kentsoeng tšebetsong naheng ea heso, tse maemong a pele lefatšeng ka bophara ka bongata le ka botlalo.

Lipalopalo le Ponelopele ea Tšebeliso ea Mashala a Phepelo ea Motlakase oa Mashala Chaena ho tloha ka 2010 ho isa 2020.

2.Main Chromium Molybdenum Steel Welding Rod Products

Letlapa la 2 Pontšo ea ts'ebetso ea li-electrode tsa tšepe tse sa keneleng mocheso oa pearlitic

| Ntho | Motsoako o ka sehloohong | Mocheso℃*H | Boitšoaro ba mechine | ||||

| Khefutsa Mpa | Tensile Mpa | Eketsa % | Ho tshoha J/℃ | ||||

| GER-107 | 0.5%Mo | 620*1 | 477 | 570 | 24.0 | 152/0 | - |

| GER-207 | 0.5%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 143/0 | - |

| GER-307 | 1.25%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 146/0 | - |

| GER-317 | 1.25%Cr-0.5%Mo-V | 730*2 | 541 | 635 | 22.5 | 166/0 | - |

| GER-407 | 2.25%Cr-1%Mo | 690*1 | 586 | 682 | 21.0 | 142/0 | - |

| GER-417 | 2.25%Cr-1%Mo-V | 720*8 | 556 | 657 | 21.0 | 145/-18 | 120/-30 |

| GER-507 | 5%Cr-0.5%Mo | 740*1 | 490 | 605 | 23.0 | 124/0 | - |

Hlokomela:

1. Khampani ea rona e hlahisitse EXXXX-15, EXXXX-16, EXXXX-18 le lihlopha tse ling tsa li-slag tsa ho roala bakeng sa li-electrode tsa sehlopha se le seng ho finyella litlhoko tse fapaneng tsa 'maraka. Lintlha tse ka holimo li bontša feela ts'ebetso ea li-electrode tsa EXXXX-15.

3.2 Lethathamo la li-electrode tsa tšepe tse sa keneleng mocheso le tse matla haholo (ultra)

| ITEM | TS'ELISO | Motho ea ka Sehloohong |

| GER-707 | AWS A5.5 E8015-B8 GB/T 5118 E6215-9C1M | 9% Cr-1% Mo Carbon steel core terata, motsoako oa mantlha oa alloy o fetotsoe ho tloha ho koae, o loketse li-unit tsa subcritical tsa matla a mocheso, A213-T9, A335-P9 tšepe ea tšepe (ea moruo le e sebetsang, e sebetsang hantle) |

| GER-91 Mofuta oa mantlha | AWS A5.5 E9015-B91 GB/T 5118 E6215-9C1MV | 9% Cr-1% Mo-Nb-vn E loketse li-unit tsa bohlokoa tsa matla a futhumatsang, T / P 91 welding ea tšepe, motsoako o ka sehloohong oa alloy o fetisoa ho tloha mokokotlong oa welding, microstructure e phahameng ea mocheso le botsitso ba ts'ebetso. |

| GER-91M motsoako oa letlalo la lithethefatsi | 9% Cr-1% Mo-Nb-VN E loketse li-unit tsa bohlokoa tsa matla a mocheso, T / P 91 tšepe welding, motsoako o ka sehloohong oa motsoako o fetisoa ho tloha mokokotlong oa welding, microstructure e phahameng ea mocheso le botsitso ba ts'ebetso. | |

| GER-92 Mofuta oa mantlha | AWS A5.5 E9015-B92 | 9% Cr-0.5% Mo-WV-Nb-N E loketse li-unit tsa matla a phahameng a mocheso, T / P 92 tšepe welding, motsoako o ka sehloohong oa alloy o fetoloa ho tloha terata ea mantlha, mocheso o phahameng oa mocheso le botsitso ba ts'ebetso. |

| GER-93 | Tekanyetso ea rona | 9%Cr-3%W-3%Co-Cu-V-Nb-B E loketse ho tjheseletsa ha tšepe ea G115 e tsoetseng pele e phahameng haholo bakeng sa ho hlahisa matla a futhumetseng. E na le sebopeho se setle le botsitso ba ts'ebetso ka mocheso o phahameng. Matla a tšoarellang ke makhetlo a 1.5 a tšepe ea P92, 'me ho hanyetsa ha eona mocheso o phahameng oa oxidation oa mouoane le ho bola ho molemo ho feta ea tšepe ea P92. |

Pontšo ea ts'ebetso ea elektrode

| Ntho | Motsoako o ka sehloohong | Mocheso℃*H | Boitšoaro ba mechine | |||

| Khefutsa Mpa | Tensile Mpa | Eketsa % | Ho tshoha J | |||

| GER-707 | 9%Cr-1%Mo | 740*1 | 540 | 670 | 24.0 | 119.7 |

| GER-91 | 9%Cr-1%Mo-Nb-VN | 760*2 | 557 | 702 | 21.0 | 96.3 |

| GER-91M | 9%Cr-1%Mo-Nb-VN | 760*2 | 553 | 701 | 22.5 | 81.0 |

| GER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760*2 | 596 | 706 | 21.5 | 103.0 |

| GER-93 | 9%Cr-3%W-3%Co | 770*4 | 580 | 720 | 20.0 | 77.7 |

Hlokomela:

1. GER-91M ke phetoho ea ho roala, ke hore, mokokotlo oa welding ke mohala o tloaelehileng oa carbon steel core, 'me motsoako o ka sehloohong o fetoloa ka ho roala. Ha e bapisoa le GER-91 (mofuta oa phetoho ea terata ea mantlha), e na le melemo e metle ea moruo ebile ke ea rona e holimo Lihlahisoa tse ka sehloohong tsa lithupa tsa welding bakeng sa matla a maholo a mocheso.

3.Phetolelo ea 2015 ea ASME standard e hloka E9015-B91 electrode Mn + Ni≤1.4%, 'me phetolelo ea 2017 e hloka ≤1.2% bakeng sa tšepe ea motheo. (Mofuta oa morao-rao oa 2021 oa ASME o tsoela pele ho sebelisa mofuta oa 2015 oa litlhoko tsa sebopeho sa ASME bakeng sa li-electrode tsa E9015-B91/ B92). E le ho finyella tlhokahalo ea 'maraka, li-welding rods tsa rona tsa E9015-B91 le E9015-B92 li thehile mefuta e' meli ea lisebelisoa tse tsamaisanang tsa welding: Mn + Ni≤1.4% le Mn + Ni≤1.2%. Hobane ea morao-rao e na le tlhokahalo e eketsehileng ea 'maraka, tse ka holimo li bontša li-electrode tsa 91/92 li kenngoa tšepe Mn + Ni≤1.2%.

4. Pontšo ea tlhahlobo ea ts'ebetso bakeng sa li-electrode tsa ultra-supercritical

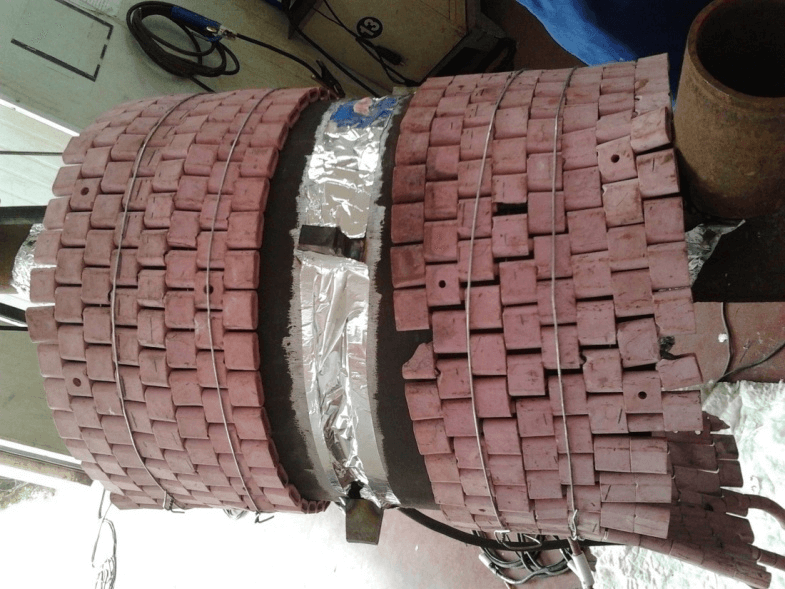

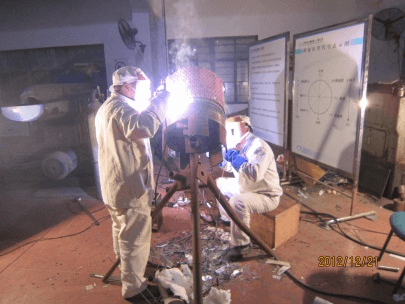

4.1 Tlhokomelo ea ts'ebetso ea likhokahano tse cheselitsoeng tsa P91/92

6. Melemo le litšoaneleho tsa li-electrode tsa tšepe tse sa keneleng mocheso bakeng sa tšepe ea chrome-molybdenum

1. Ho na le mefuta e mengata le mefuta eohle

●Moetso o tloha ho 0.5%Mo ho isa ho 9%Cr-3%W-3%Co.

●Sebelisa mocheso ho tloha 500℃ ho isa 650℃.

● Mebala e fapaneng ea ho roala le mefuta ea ho roala (EXXXX-15, EXXXX-16, EXXXX-18) e ka sebelisoa liketsahalong tse fapaneng (mofuta o akaretsang, mofuta o matla oa arc bakeng sa lipeipi tsa kaho ea motlakase).

● E ka finyella litlhoko tsa ho cheselletsa litšepe tse ngata tsa Cr-Mo.

2. Ts'ebetso e ntle

Thepa e ntle haholo ea mochini, ts'ebetso e ntle ea mocheso o phahameng (mocheso o phahameng o nyoloha le thepa ea botsofali e phahameng).

3. Boqapi bo botle

Electrode e na le manufacturability e babatsehang maemong ohle, ho chesa ha li-arc tse tsitsitseng, ho satalla hantle le ho foka matla, spatter e nyenyane, metsi a matle, sebōpeho se setle sa weld, le ho tlosoa ha slag habonolo ka mor'a ho tjheseletsa.

4. Indasteri e etellang pele

E sebelisana le Suzhou Institute of Thermal Engineering, 'me e fetisitse tlhahlobo ea "T / P 91/92 Localization Appraisal Meeting" ka 2015,' me e sebelisana le lihlopha tse kholo tsa matla a malapeng tse kang Shenhua Guohua le General Iron and Steel Research Institute ho hlahisa 650 ° C. Litšepe tsa G115 tse tšehetsang lisebelisoa le lits'ebetso, 'me li ile tsa tšoara liboka tse ngata tsa phapanyetsano ea lisebelisoa tsa ho cheselletsa.

More information send to E-mail: export@welding-honest.com

Nako ea poso: Dec-27-2022