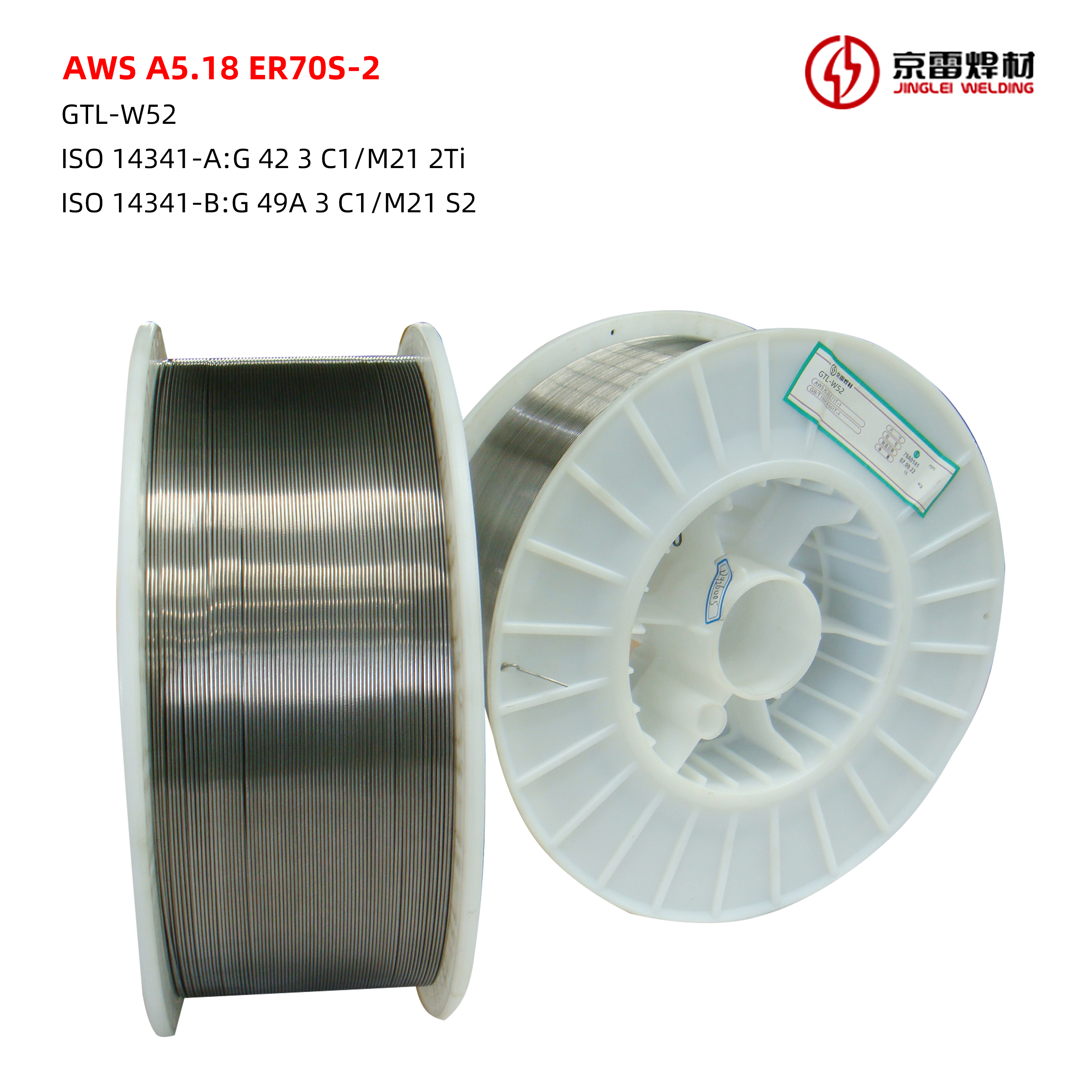

Litšepe tse phahameng tsa Carbon Terata e tiileng ea ER70S-2 lisebelisuoa tsa masela tsa weld

E loketse bakeng sa welding ea lipeipi, sekepe sa khatello, indasteri ea petrochemical joalo-joalo.

Litšobotsi ke life?

●Ka lebaka la tlatsetso ea AI, Ti, Zr le likarolo tse ling tsa tšepe, e ka sebelisoa ho cheselletsa mafome le litšila holim'a tšepe; Ho fepa ka terata e boreleli, arc e tsitsitseng, sebopeho se setle, phallo e ntle ea tšepe e qhibilihisitsoeng, ho phatloha ho fokolang, ka ts'ebetso e ntle ea ts'ebetso ea welding; Tšepe e qhibilihisitsoeng e na le thepa e tsitsitseng ea mochini le ts'ebetso e ntle haholo ea mocheso o tlase

Parameter ea sehlahisoa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Tse ding |

| GB/T MELAO | 0.053 | 0.51 | 1.08 | 0.01 | 0.003 | 0.01 | 0.04 | 0.06 | Ti:0.10 Al:0.07 Zr:0.06 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | ||||

| GB/T MELAO | 475 | 550 | 32 | 80/-30 | AW | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1 | 1.2 | 1.6 | |||||

| MOTLATSI (Amp) | H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | ||||||

Mokhoa oa ho tsamaisa

●Sepalangoang sa makoloi

●Ho tsamaisa ka sekepe

Sebaka sa rona sa polokelo

Re kenya letsoho lenaneong

●Tšebeliso ea matla a futhumatsang

●Tanka ea polokelo ea Shanghai Morimatsu

Lihlahisoa tsa rona ho lefatše

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Tse ding |

| GB/T MELAO | 0.053 | 0.51 | 1.08 | 0.01 | 0.003 | 0.01 | 0.04 | 0.06 | Ti:0.10 Al:0.07 Zr:0.06 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | Phekolo ea mocheso °C*h | ||||

| GB/T MELAO | 475 | 550 | 32 | 80/-30 | AW | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1 | 1.2 | 1.6 | |||||

| MOTLATSI (Amp) | H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | ||||||

Ngola molaetsa wa hao mona mme o re romele wona