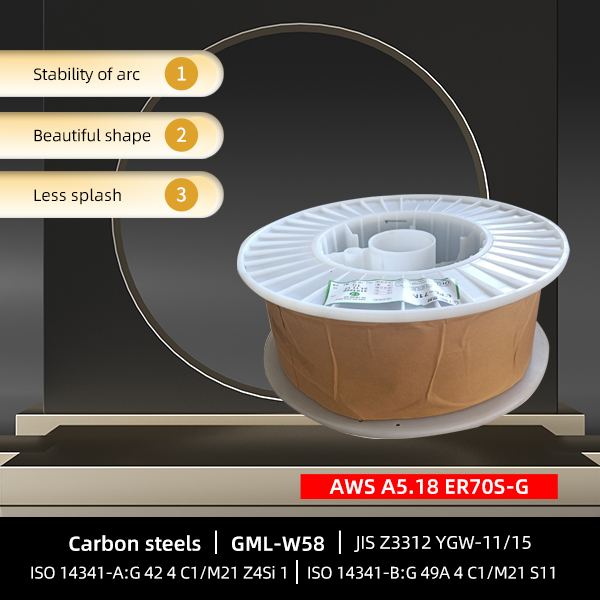

Litšepe tse phahameng tsa Carbon MIG ER70S-G weld fabrication joints

Kopo

E loketse bakeng sa kaho ea likepe, borokho, kaho le lits'ebetso tsa ho cheselletsa tjheseletsa, hape e sebelisoa ka mokhoa o phahameng oa hona joale oa ho tjheseletsa butt, fillet welding le cross welding.

Tekanyetso eo re kopaneng le eona: GB/T8110 G 49A4 C1/M21 S11 N , AWS A5.18 ER70S-G & A5.18M ER49S-G, ISO14341-A:G 42 4 C1/M21 Z4Si1, ISO 14341-A:G 4 C1/M21 S11

JIS Z3312 YGW-11/15

Boikhethelo

Tšireletso ea tikoloho le bophelo bo botle, 'me e ka qoba phello e mpe ea koporo holim'a boleng ba welding;

Ho phaella ho likarolo tse nepahetseng tsa alloying tse kang Si le Mn, likarolo tse lekaneng tsa Ti li kenngoa ho tsitsisa arc le ho etsa hore phetoho ea arc e hloekisoe; Palo e lekanyelitsoeng ea ho phatloha le mosi le eona e fokotsehile haholo;

Ti e na le karolo ea ho ntlafatsa lijo-thollo tsa weld pass, e le hore ho tiea ha weld pass ho ntlafatsoe haholo, 'me e ka boela ea bapala ts'ebetso ea eona e phahameng ka ho fetisisa ea ho phalla ho phalla.

Hlahisa lintlha

Matla a ntlafalitsoeng haholo

High hona joale welding e ka boela ea bapala ts'ebetso ea eona e phahameng

Mabapi le rona

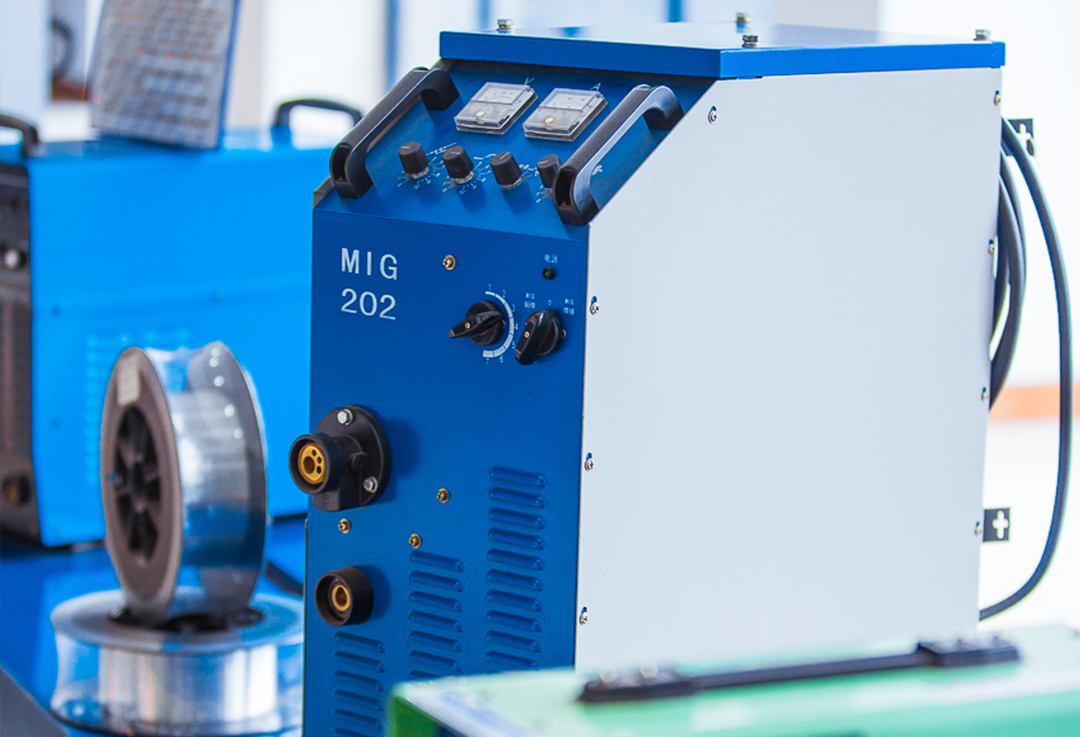

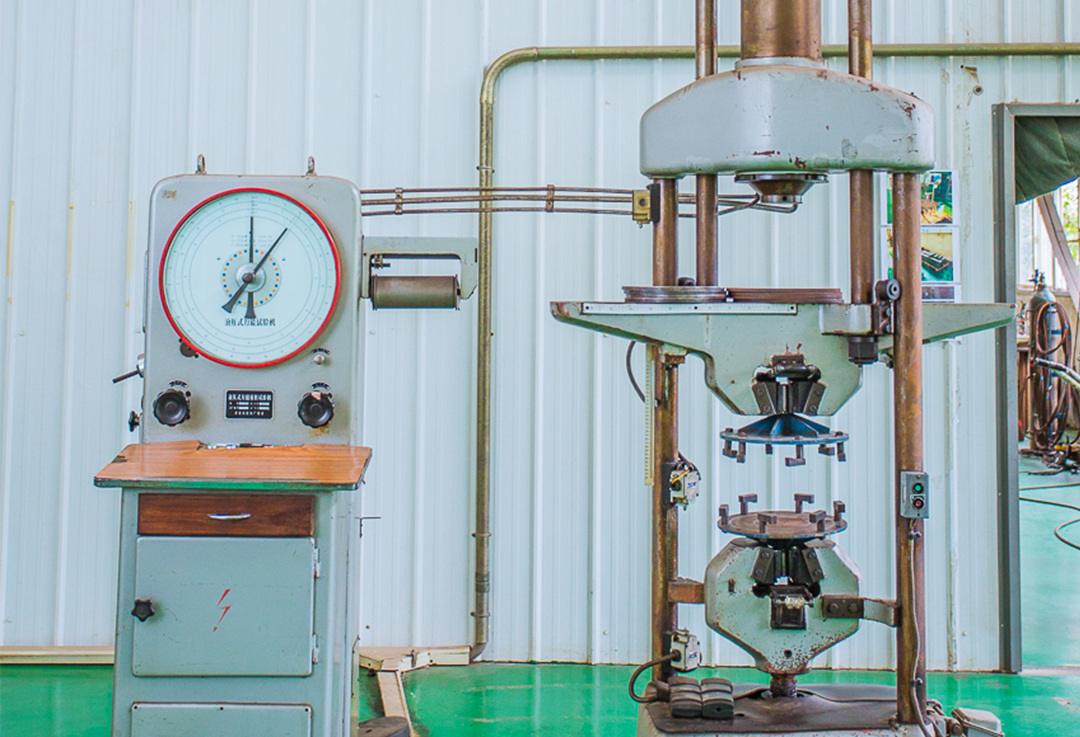

Pontšo ea fektheri ea fioor

Nyeoe ea kopo

Morero oa LNG oa Canada

Hainan Huasheng phenol recovery tower

Lithunya tsa 'nete tsa feme

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Ti+Zr | P | S | Cu |

| GB/T MELAO | 0.02-0.151 | 0.40-1,90 | 0.55-1.10 | - | - | - | 0.02-0.30 | 0.300 | 0.030 | 0.50 |

| MOLAO OA MOLAO | - | - | - | - | - | - | - | - | - | - |

| MOHLALA BOHLOKOA | 0.055 | 1.500 | 0.85 | 0.03 | 0.02 | 0.01 | 0.18 | 0.013 | 0.010 | 0.02 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | |||||

| GB/T MELAO | 390 | 490-670 | AW | 27/-40 | 18 | |||||

| MOLAO OA MOLAO | 400 | 490 | AW | - | 22 | |||||

| MOHLALA BOHLOKOA | 500 | 590 | AW | 78/-40 | 28 | |||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1 | 1.2 | 1.6 | |||||

| MOTLATSI (Amp) | H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | ||||||