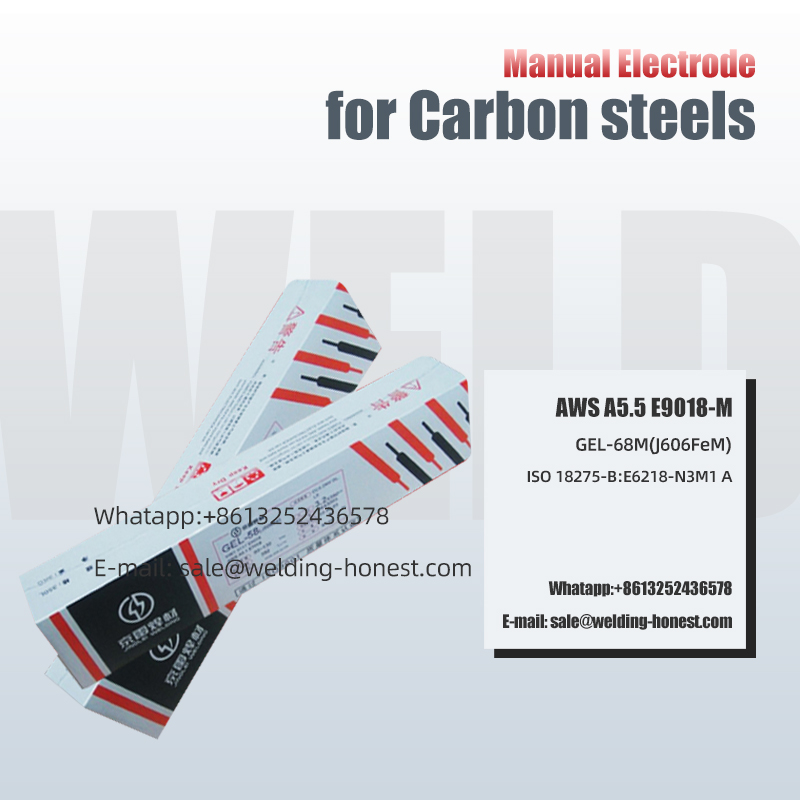

High Carbon Steels Manual Electrode E9018-M VLCC sekepe se rekisoang ka oli e tala

E loketse boemo bo tšoanang ba matla a tšepe e tlase ea alloy welding.

Tekanyetso eo re kopaneng le eona: GB/T32533 E6915-4M2P, AWS A5.5 E10015-D2 & A5.5M E6915-D2, ISO18275-A:E 62 5 Mn1NiMo B 4 2, ISO 18275-B: E6915-4.

Ke eng tse

characieristics?

●620Mpa kereiti ea matla a phahameng kereiti e matla toughness tšepe phofo tlaase hydrogen electrode.

●Sebaka sa weld se boreleli, arc e tsitsitse, ho phatloha ho nyane.

●The desagging ke bonolo, melting bokgoni phahameng.

●Likahare tsa haedrojene tse pharalletseng tse tlase, khanyetso e ntle ea crack, thepa e tsitsitseng ea mochini.

Parameter ea sehlahisoa

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.10 | 0.6-1,25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| MOLAO OA MOLAO | 0.10 | 0.6-1,25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| MOHLALA BOHLOKOA | 0.068 | 1.10 | 0.26 | 0.04 | 1.50 | 0.26 | 0.011 | 0.007 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 540-620 | 620 | - | 27/-50 | 21 | ||||

| MOLAO OA MOLAO | 540-620 | 620 | - | 27/-50 | 24 | ||||

| MOHLALA BOHLOKOA | 605 | 700 | - | 90/-50 | 24 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Shebang tsela

re tsamaisa

●Sepalangoang sa makoloi

●Ho tsamaisa ka sekepe

Sheba

ntlo ea rona

Merero

re kenya letsoho ho

●Harbin motlakase liheke tse tharo tsa CMT

●China-Russia ka bochabela pele

Lihlahisoa tsa rona

lefatsheng

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.10 | 0.6-1,25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| MOLAO OA MOLAO | 0.10 | 0.6-1,25 | 0.80 | 0.15 | 1.4-1.8 | 0.35 | 0.030 | 0.030 | 0.05 |

| MOHLALA BOHLOKOA | 0.068 | 1.10 | 0.26 | 0.04 | 1.50 | 0.26 | 0.011 | 0.007 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 540-620 | 620 | - | 27/-50 | 21 | ||||

| MOLAO OA MOLAO | 540-620 | 620 | - | 27/-50 | 24 | ||||

| MOHLALA BOHLOKOA | 605 | 700 | - | 90/-50 | 24 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||