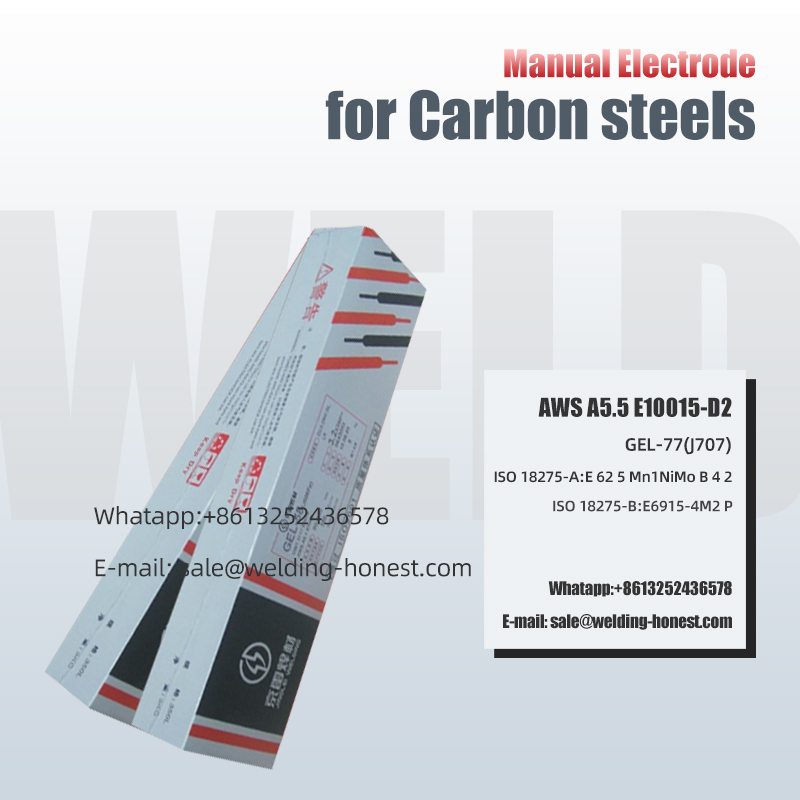

High Carbon steels Manual electrode E7018-1 weld fabrication stuff

Kopo

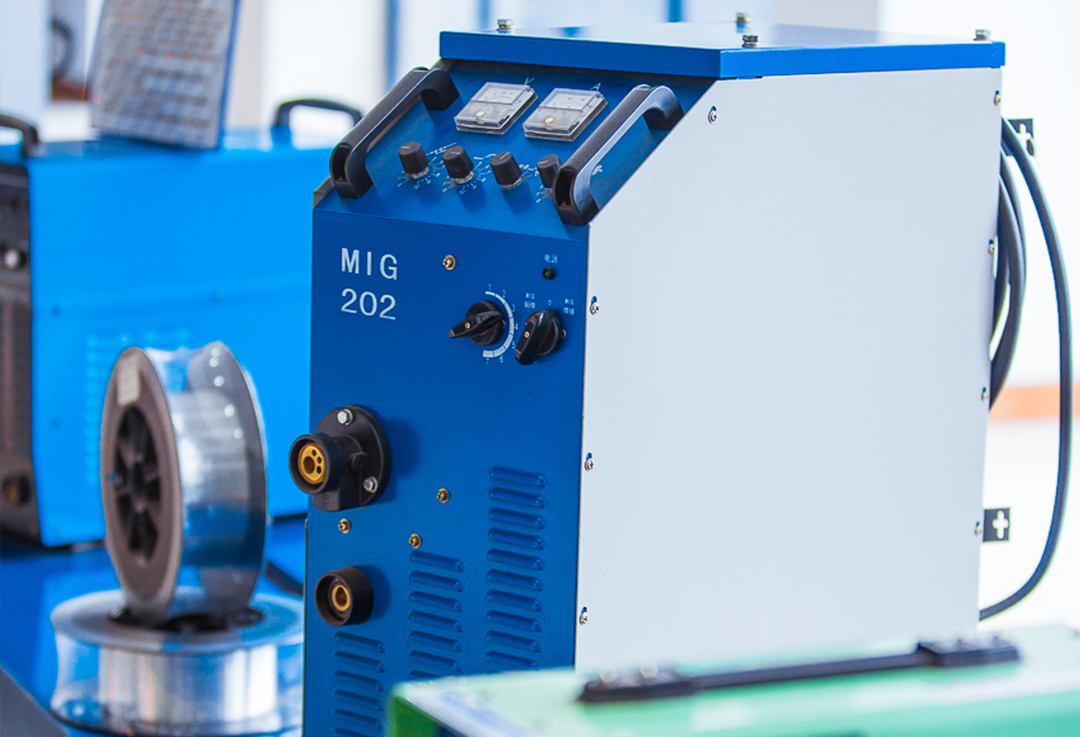

E Loketse HO TŠELISOA TŠEPE EA KHABONE LE TŠEPE EA KHABANE LE LOW ALLOY, MMOHO LE MATLA A TABAPILENG A Boenjineri ba Matla a Nyutlelie, MOAHO, BOROHO LE LITABA tse ling, JOALOKA Q345.

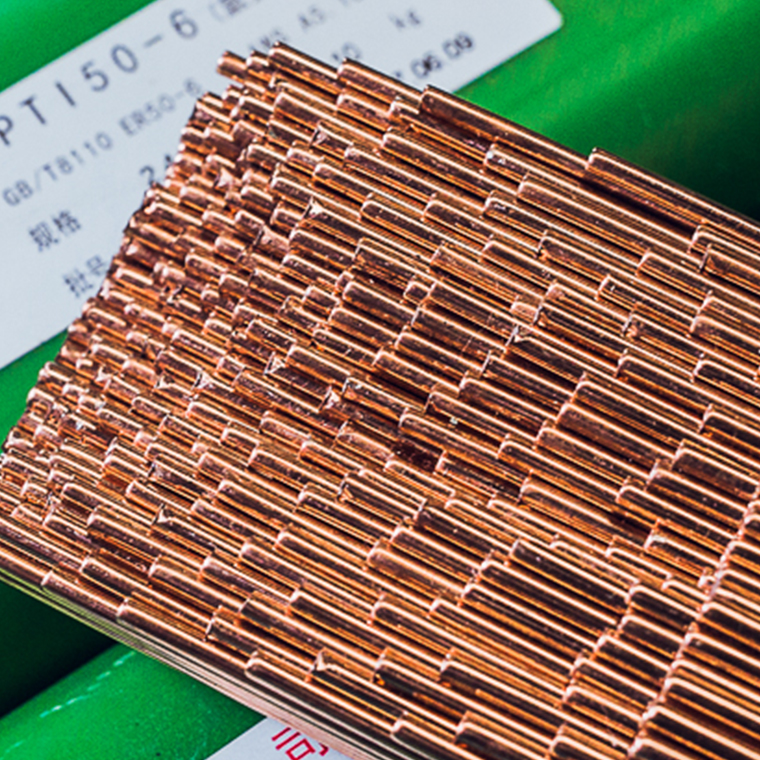

Tekanyetso eo re kopaneng le eona: GB/T5117 E5018-1, AWS A5.1 E7018-1 & A5.1M E4918-1, ISO2560-A:E 42 5 B 3 2 H5, ISO 2560-B: E4918-1 A.

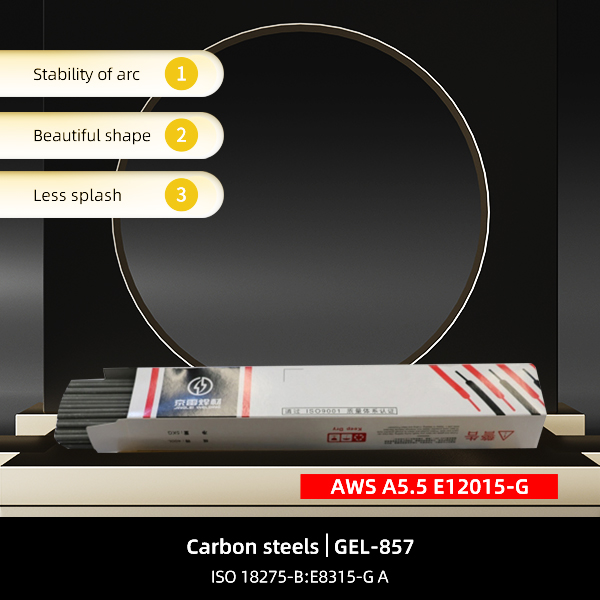

Boikhethelo

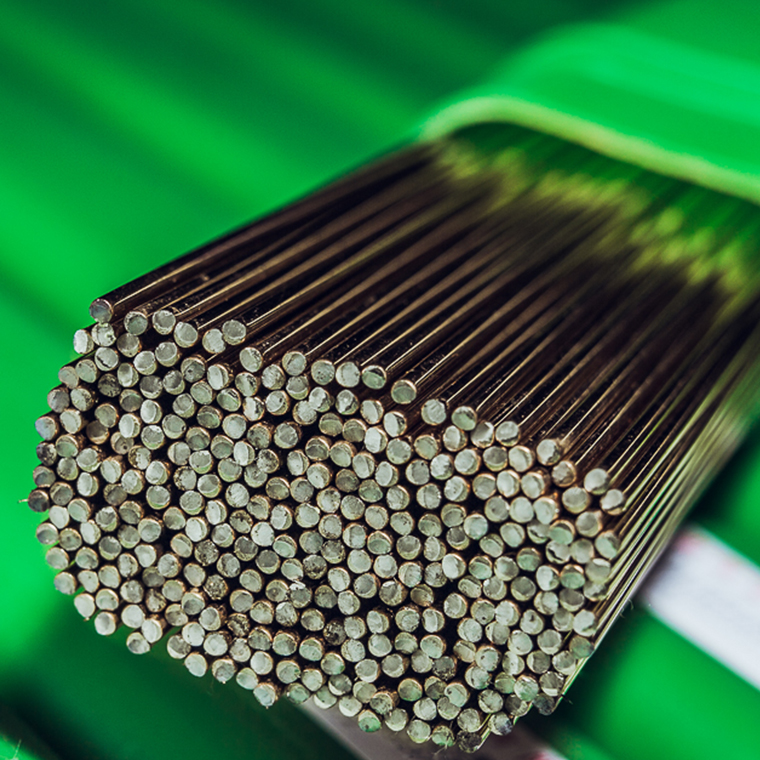

Iron powder low hydrogen type elektrode tsa letsoho, ts'ebetso e phahameng ea welding, arc e tsitsitseng, sebopeho se setle, corrugations.

Ho phatloha ho honyenyane, ho tlosoa ha slagging habonolo, ho hanyetsa mollo oa letlalo la lithethefatsi hantle, ho hanyetsa stomatal hantle.

Thepa e tsitsitseng ea mochini, polasetiki e ntle le mocheso o tlase o ama ho tiea.

Hlahisa lintlha

Hlakola hanyane haholo

Slagging e bonolo

Mabapi le rona

Pontšo ea fektheri ea fioor

Nyeoe ea kopo

Harbin Electric - Sanmen, Haiyang MSR

Qinghai Youjian Wunan Oilfield

Lithunya tsa 'nete tsa feme

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.15 | 1.60 | 0.90 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| MOLAO OA MOLAO | 0.15 | 1.60 | 0.75 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| MOHLALA BOHLOKOA | 0.065 | 1.40 | 0.45 | 0.03 | 0.01 | 0.006 | 0.011 | 0.007 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 400 | 490 | AW | 27/-45 | 20 | ||||

| MOLAO OA MOLAO | 400 | 490 | AW | 27/-45 | 22 | ||||

| MOHLALA BOHLOKOA | 490 | 590 | AW | 128/-45 | 28 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||