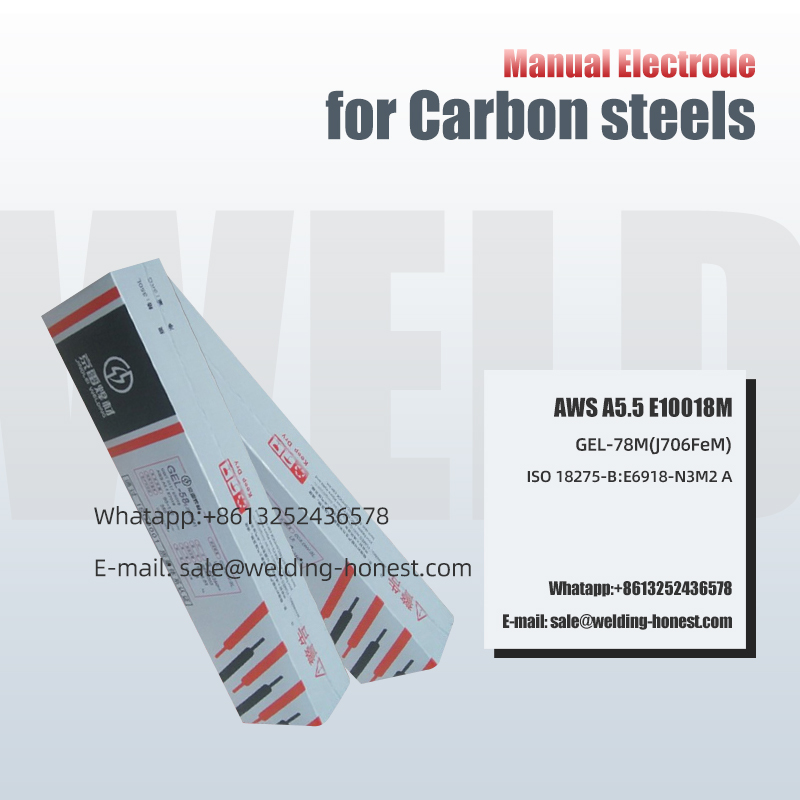

High Carbon steels Manual electrode E11018M Soldering stuff

Kopo

E loketse bakeng sa tjheseletsa ea tšepe e tlase ea alloy ea matla a tšoanang mochining oa kaho, joalo ka Q690, jj.

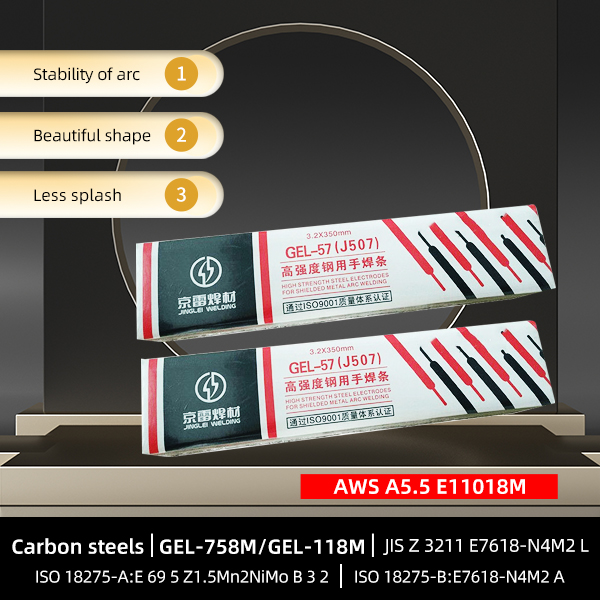

Tekanyetso eo re ileng ra kopana le eona: GB/T32533 E7618-N4M2, AWS A5.5 E11018M & A5.5M E7618M, ISO18275-A:E 69 5 Z1.5Mn2NiMo B 3 2, ISO 18275-B: E76M2 Z3 J-N1 E 7618-N4M2L.

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.10 | 1.30-1,80 | 0.60 | 0.40 | 1.25-2,50 | 0.25-0,50 | 0.030 | 0.030 | 0.05 |

| MOLAO OA MOLAO | 0.10 | 1.30-1,80 | 0.60 | 0.40 | 1.25-2,50 | 0.25-0,50 | 0.030 | 0.030 | 0.05 |

| MOHLALA BOHLOKOA | 0.067 | 1.69 | 0.3 | 0.13 | 2.29 | 0.38 | 0.007 | 0.004 | 0.007 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 680-760 | 760 | AW | 27/-50 | 18 | ||||

| MOLAO OA MOLAO | 400 | 490 | AW | 27/-50 | 20 | ||||

| MOHLALA BOHLOKOA | 415 | 570 | AW | 80/-50 | 22 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Boikhethelo

Iron phofo e tlase ea hydrogen potassium letsoho la electrode, e sebetsang hantle haholo.

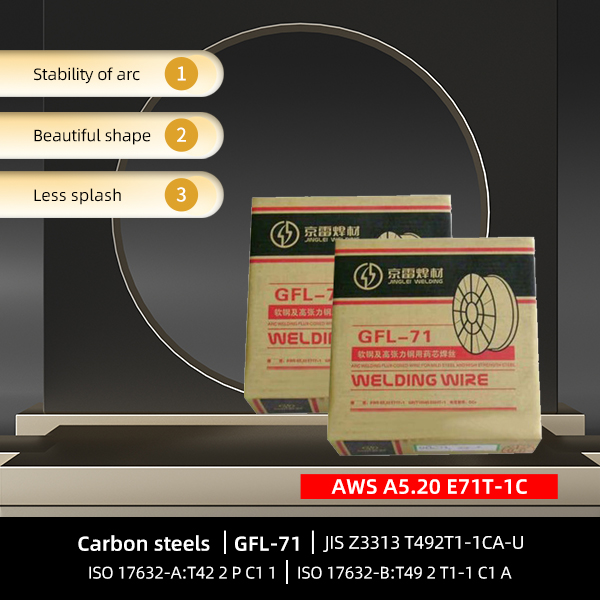

Arc e tsitsitseng, ho phatloha ho honyenyane, ho bōptjoa hantle, ho senya habonolo.

Ts'ebetso ea X-ray e ntle, e tsitsitseng thepa ea mochini.

Hlahisa lintlha

Ho tsitsa ha arc

Sebopeho se setle

Mabapi le rona

Pontšo ea fektheri ea fioor

Nyeoe ea kopo

Lisebelisoa tsa ho cheselletsa libotlolo tsa koloi ea LNG

Polypropylene reactor

Lithunya tsa 'nete tsa feme

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.10 | 1.30-1,80 | 0.60 | 0.40 | 1.25-2,50 | 0.25-0,50 | 0.030 | 0.030 | 0.05 |

| MOLAO OA MOLAO | 0.10 | 1.30-1,80 | 0.60 | 0.40 | 1.25-2,50 | 0.25-0,50 | 0.030 | 0.030 | 0.05 |

| MOHLALA BOHLOKOA | 0.067 | 1.69 | 0.3 | 0.13 | 2.29 | 0.38 | 0.007 | 0.004 | 0.007 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 680-760 | 760 | AW | 27/-50 | 18 | ||||

| MOLAO OA MOLAO | 400 | 490 | AW | 27/-50 | 20 | ||||

| MOHLALA BOHLOKOA | 415 | 570 | AW | 80/-50 | 22 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Ngola molaetsa wa hao mona mme o re romele wona