Litšepe tse phahameng tsa Carbon CO2 Sireletsa E70T-1C Flux cored wire welding accessories

Kopo & Maemo

1. E loketse bakeng sa tjheseletsa e bataletseng le fillet welding ea likepe, Bridges, mechine, likoloi le mehaho ea tšepe.

2. Tekanyetso eo re e fihletseng:

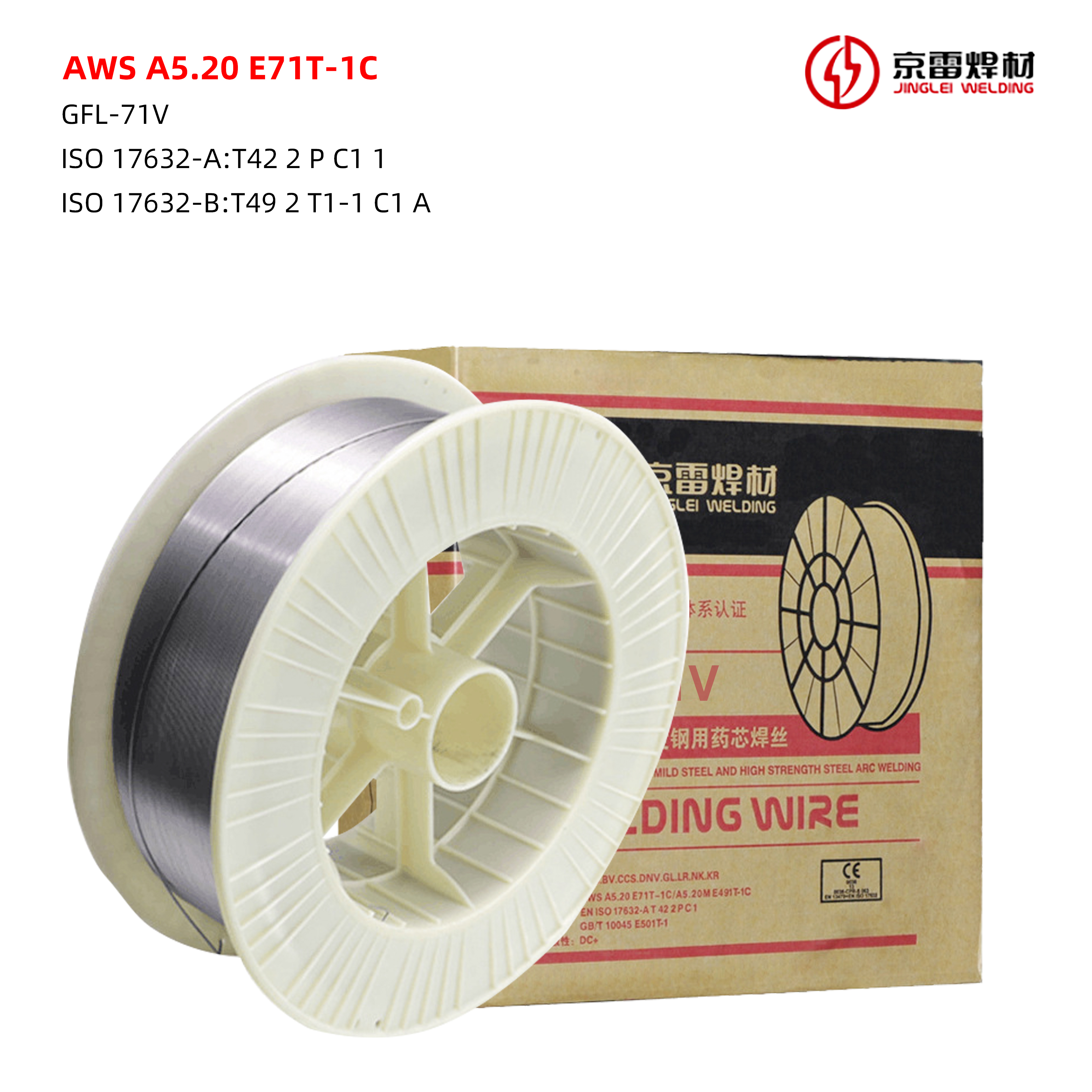

GB/T10045 T49 2 T15-0 C1 A, AWS A5.20 E70T-1C & A5.20M E490T-1C, ISO17632-A:T 42 2 R C1 3, ISO 17632-B:T49 2 T15-1 C1 AJIS Z3313 T492T15-1CA-U

3.E ka sebelisoa bakeng sa tjheseletsa ea tšepe e entsoeng ka tšepe kapa poleiti e teteaneng e bohareng.

Likaroloana

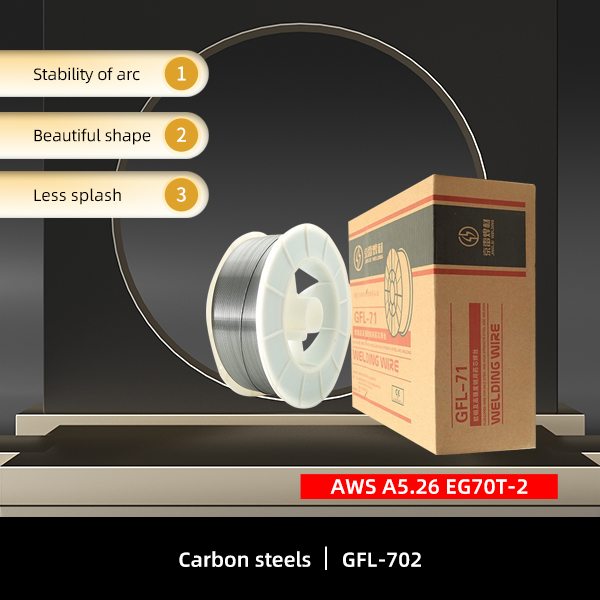

1. The arc e bonolo ebile e tsitsitse, ha ho na ho phatloha ho fokolang, ho theha hantle, ho tlosoa ha slag hantle, soot e fokolang, e nang le ts'ebetso e ntle ea ts'ebetso ea welding.

2. Ho hanyetsa ka mokhoa o babatsehang ho priming, ho hanyetsa hantle ho porosity le crack.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| MOLAO OA MOLAO | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| MOHLALA BOHLOKOA | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| MOLAO OA MOLAO | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| MOHLALA BOHLOKOA | 500 | 575 | AW | 60/-20 | 27 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

HLOKOMELA:

CO2 Sireletsa khase, ho futhumatsa pele:150±15℃

SETITIFICATION SEBALA: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

LIEKETSENG TS'OANE

Litifikeiti

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| MOLAO OA MOLAO | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| MOHLALA BOHLOKOA | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | ||||

| GB/T MELAO | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| MOLAO OA MOLAO | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| MOHLALA BOHLOKOA | 500 | 575 | AW | 60/-20 | 27 | ||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

HLOKOMELA:

CO2 Sireletsa khase, ho futhumatsa pele:150±15℃

SETITIFICATION SEBALA: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS