terata ea tjheseletsa ea SAW e shebaneng ka thata le lintho tsa ho etsa lintho tse entsoeng ka welding flux

Kopo & Maemo

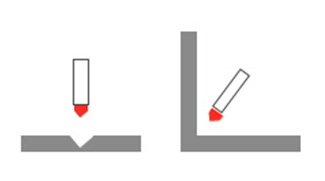

Electrode ena e thata ea letsoho e hananang le WEAR e loketse haholo ts'usumetso e tlase, likarolo tse ts'oeroeng tse matla, joalo ka mochini oa kaho ea sechaba o nchafatsang, haholo mechini ea ho hula, bakete, pompo e monyang lehlabathe. Surfacing ke mokhoa oa ho tjheseletsa oo bokaholimo kapa moeli oa likarolo tsa tšepe o kopantsoeng le lera la ho hanyetsa, ho hanyetsa kutu, ho hanyetsa mocheso o phahameng le litšobotsi tse ling tsa thepa ea tšepe. Ho lokisa le ho ntlafatsa bophelo ba ts'ebeletso ea likarolo, tšebeliso e sebetsang ea lisebelisoa tse tala, ho ntlafatsa ts'ebetso ea sehlahisoa, taolo ea litšenyehelo e na le melemo e hlakileng ea moruo. Tekanyetso ea holim'a holim'a metsi e rarahane haholo. Hoa hlokahala ho amohela mohala o loketseng oa welding ho latela melao e fapaneng. Mekhoa e fapaneng ea holim'a holim'a metsi e lokela ho sebelisoa bakeng sa likarolo tse fapaneng tsa tšepe le li-electrode tse holimo ho fumana liphetho tse khotsofatsang tsa 'nete.

Likaroloana

Ena ke mofuta o tlase oa sodium hydrogen coating surfacing electrode, boima bo phahameng, ha ho na tlhoko ea kalafo ea mocheso, e ke keng ea tsoela pele ho itšeha, ho hanyetsa hantle. Ts'ebetso e nepahetseng ea Wear - e hanyetsanang le ts'ebetso e ka netefatsa hore letlalo lohle le ka qhibiliha ka har'a letamo le qhibilihisitsoeng ka har'a arc nakong ea fusion welding. 'Me tšepe ea weld core, substrate e holim'a metsi e qhibiliha ka potlako ho hlahisa motsoako o mocha o sa sebetseng. Ka nako e ts'oanang, ho lokela ho etsoa boiteko ba ho ntlafatsa carbon content ea electrode motheong oa ho etsa bonnete ba hore lesela la welding le na le khanyetso e ntle ea crack. Khothalletsa ho thehoa ha li-carbides tse fapaneng, ho eketsa ho hanyetsa ha eona. Bakeng sa likarolo tse nang le tšusumetso le ho roala ha abrasive ka nako e le 'ngoe mosebetsing, joalo ka hlooho ea hamore ea crusher, lining plate, cage rod, joalo-joalo. mokhoa o fapaneng ka ho felletseng oa ts'ebetso o tlameha ho amoheloa.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T MELAO | 0.50-0,80 | 0.50-1,50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| MOLAO OA MOLAO | - | - | - | - | - | - |

| MOHLALA BOHLOKOA | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | 80-120 | 120-160 | 160-210 | |||||

LIEKETSENG TS'OANE

Litifikeiti

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | P | S |

| GB/T MELAO | 0.50-0,80 | 0.50-1,50 | 1.00 | 4.00-8.00 | 0.035 | 0.035 |

| MOLAO OA MOLAO | - | - | - | - | - | - |

| MOHLALA BOHLOKOA | 0.64 | 1.35 | 0.94 | 7 | 0.027 | 0.007 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | 80-120 | 120-160 | 160-210 | |||||