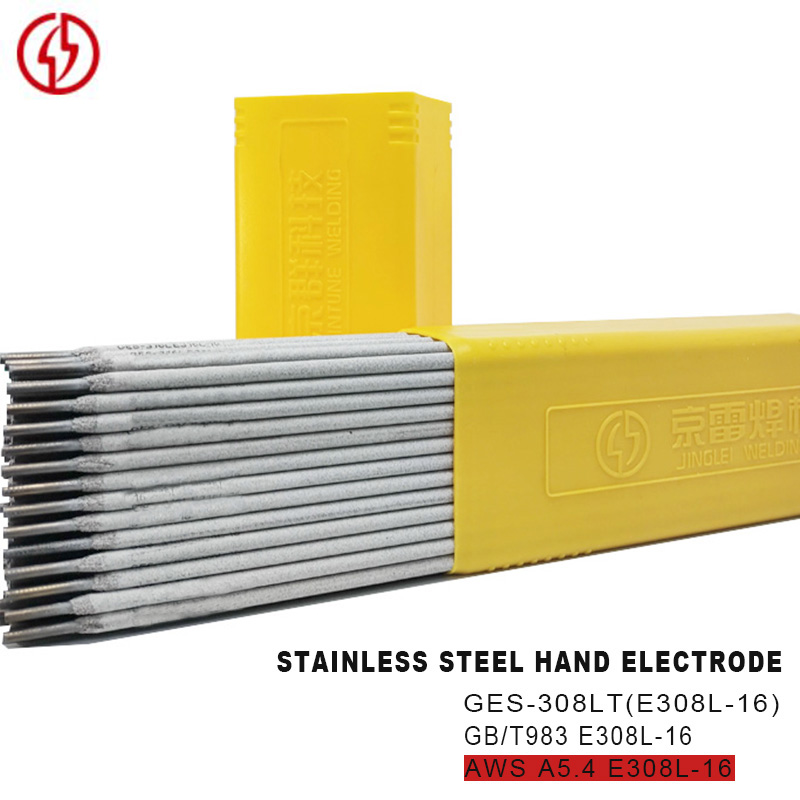

Sefahleho se thata Manual electrode weld fabrication stuff

Kopo & Maemo

GEH-547 elektrode ea letsoho e sa khoneng ho roala sefahleho se thata e sebelisoa haholo ho phahamisa le ho lokisa likarolo tse tsofetseng tsa lisebelisoa tsa lik'hemik'hale le lisebelisoa tse fapaneng tsa mochini. Joalo ka likarolo tse tlokotsing tsa slag crusher (joalo ka hamore ea crusher, hamore plate, counter plate), sesebelisoa sa ho laolla sebōpi sa samente (trei, spire, grate), mochini o lokisang litene, li-mixer blades, li-blades tsa mochini o phunyang, li-blade tsa fene ea semela sa motlakase, ho phatloha ha leloala la tšepe. sebopi chute lesela poleiti, rolara, khoune robehileng, mochine oa mashala joalo-joalo. Phello e holimo e bolela ho thatafala, ho hanyetsa le ho hanyetsa mocheso oa lera la welding, 'me tshebetso ea eona e amana le lintlha tse latelang:

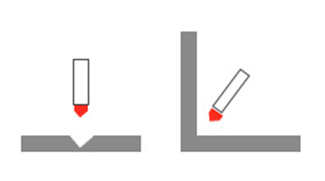

1. Boholo ba hona joale ba welding, bolelele ba arc. E kholo ea hona joale, arc e telele, lisebelisoa tsa alloying tse bonolo ho chesa, ho seng joalo, phetoho ea likarolo tse ntle tsa alloying. 2. Mocheso oa preheating le maemo a pholileng a liehang a khetholla boleng ba lera le holimo. 3. Mekhoa e fapaneng ea phekolo ea mocheso e ka sebelisoa ho fumana boima bo fapaneng ba litšepe tse ling tse holim'a metsi.

Likaroloana

GEH-547 ke mofuta o tlase oa sodium hydrogen mofuta oa chromium-nickel butt welding electrode, opereishene e ntle, ho phatloha ho fokolang, ho bonolo ho slag, sebopeho se setle, ho bonolo ho etsa ts'ebetso ea mochini; Ho matlafatsoa ha silicon ho matlafatsa ho thatafala, ho hanyetsa ha abrasion, ho hanyetsa kutu le khanyetso ea oxidation ea tšepe e holim'a metsi. Bothata bo atileng haholo bo hlahang holim'a metsi ke ho petsoha. Mekhoa e ka sehloohong ea ho thibela ho phunyeha ke e latelang: 1. Preheat pele ho welding, laola mocheso pakeng tsa lihlopha, ho lieha ho pholile ka mor'a ho cheselletsa; 2. 2. Kalafo ea mocheso ho felisa khatello ea kelello ka mor'a tjheseletsa. 3, qoba ho phatloha ho nang le mekhahlelo e mengata, u sebelisa elektrode e holimo ea mofuta oa haedrojene. 4. Pele ho welding, e hloka ho omisoa ka 300-350 ℃ bakeng sa hora e le 'ngoe; Ho hlokahala ho tlosa lintho tse bonahalang motheo holim'a mongobo, mafome litsila tse teng, oli, joalo-joalo Hape lokela ho ela hloko tsela ea arc le arc.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T MELAO | 0.18 | 0.60-2.00 | 4.80-6,40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| MOLAO OA MOLAO | - | - | - | - | - | - | - |

| MOHLALA BOHLOKOA | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | 80-120 | 120-160 | 160-210 | |||||

LIEKETSENG TS'OANE

Litifikeiti

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T MELAO | 0.18 | 0.60-2.00 | 4.80-6,40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| MOLAO OA MOLAO | - | - | - | - | - | - | - |

| MOHLALA BOHLOKOA | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| MOTLATSI (Amp) | 80-120 | 120-160 | 160-210 | |||||