Cobalt Alloys Manual electrode EDCoCr-B Welding lisebelisoa

Kopo

E ka sebelisoa bakeng sa ho phahamisa mocheso o phahameng le li-valve tsa khatello e phahameng, letsoho le phahameng la pompo ea pompo le lesela la lesela, lisebelisoa tsa lik'hemik'hale tsa fiber, sawtooth, screw push rod, joalo-joalo.

Boikhethelo

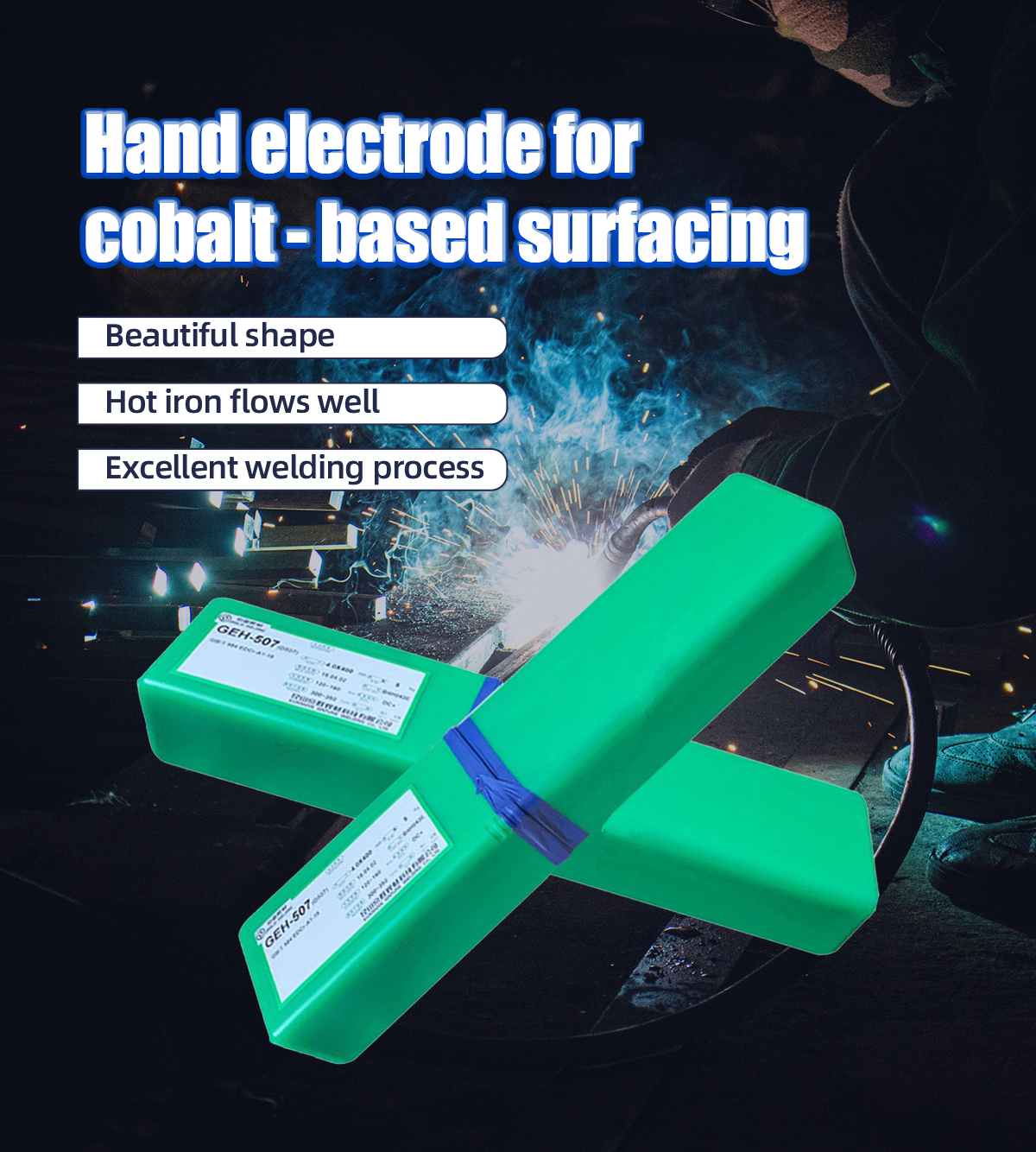

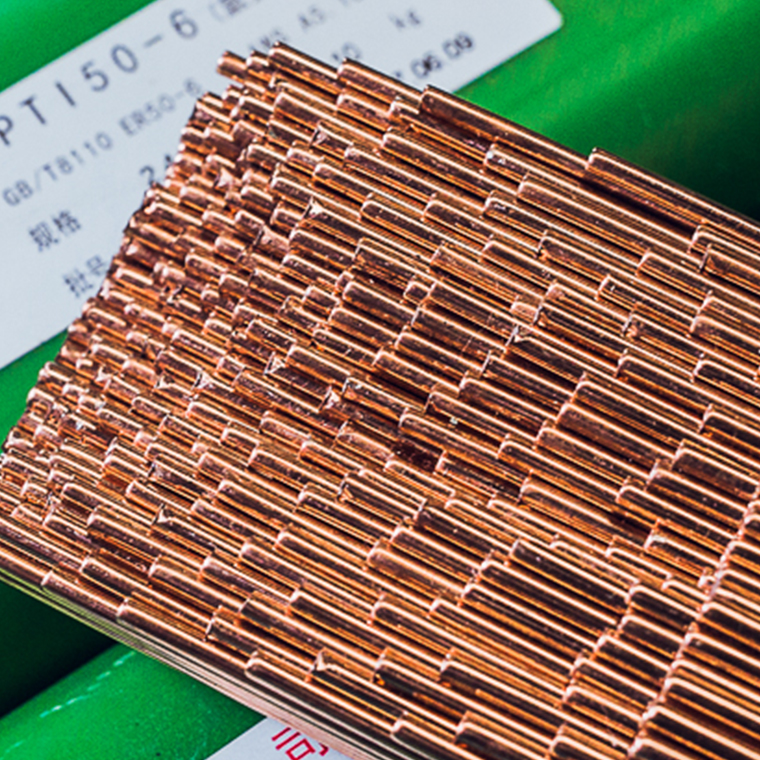

Electrode e holim'a cobalt e entsoeng ka titanium-calcium e nang le motsoako oa cobalt-chromium-tungsten joalo ka ha terata ea mantlha e lokela ho amoheloa.

Sebelisa DC reverse connection.

Litšepe tse holim'a metsi li ka boloka ts'ebetso e ntle le ho hanyetsa kutu ho 650 ℃.

Hlahisa lintlha

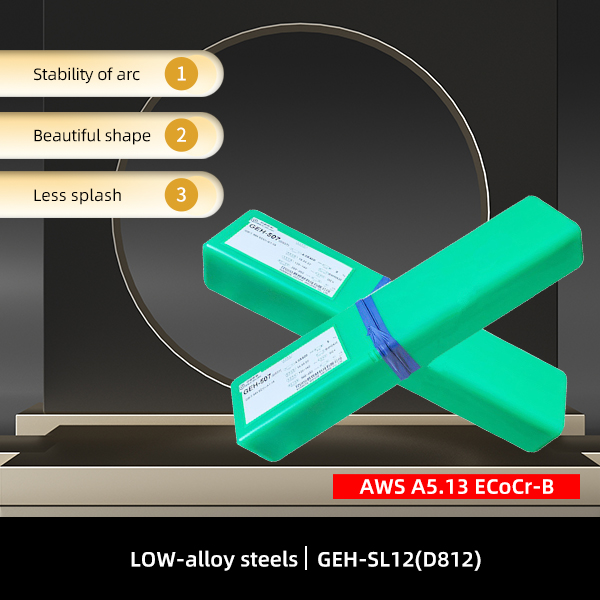

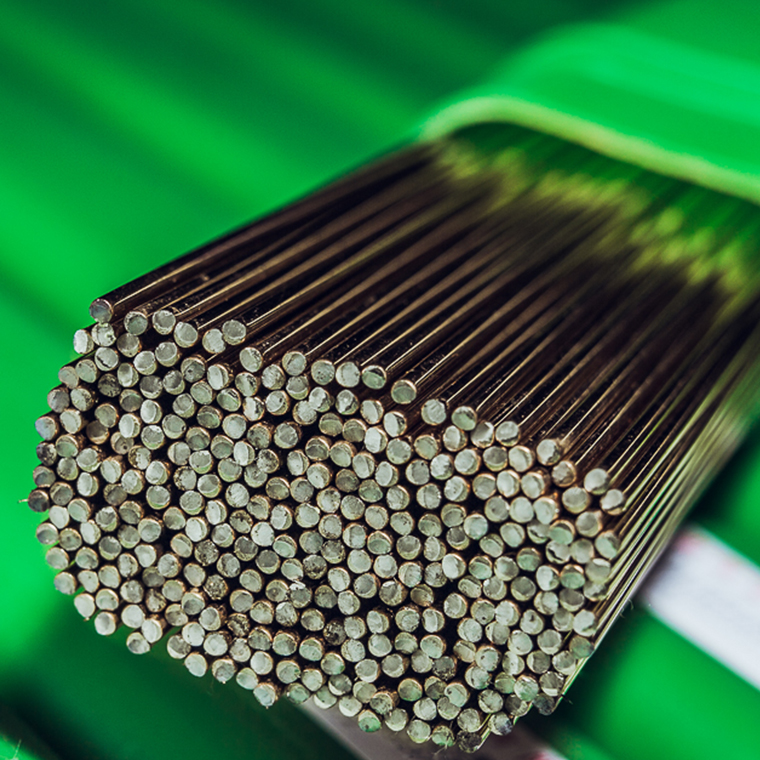

Sebopeho se setle

Sebopeho se setle

Mabapi le rona

Pontšo ea fektheri ea fioor

Nyeoe ea kopo

Sino-russian Eastern Front

Hainan Huasheng phenol recovery tower

Lithunya tsa 'nete tsa feme

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T MELAO | 1.00-1.70 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 7.00-10.00 | Margin |

| MOLAO OA MOLAO | 1.0-1.7 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 7.0-9.5 | Margin |

| MOHLALA BOHLOKOA | 1.15 | 1.31 | 1.12 | 30.5 | 2.4 | 0.1 | 3.500 | 8.3 | Margin |

WELD PASS HARDNESS:

Mohlala oa boleng HRC=46

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Ngola molaetsa wa hao mona mme o re romele wona