Cobalt alloys Manual electrode ECoCr-A Welding thepa

Kopo

E sebelisetsoa ho phahamisa mocheso o phahameng le li-valve tsa khatello e phahameng, li-shear tse chesang, li-valve tsa enjene, li-blade tsa turbine, joalo-joalo.

Boikhethelo

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T MELAO | 0.70-1,40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Margin |

| MOLAO OA MOLAO | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Margin |

| MOHLALA BOHLOKOA | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Margin |

WELD PASS HARDNESS:

Mohlala oa boleng HRC=46

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Titanium-calcium e koahetsoeng ka cobalt e thehiloeng holim'a electrode e lokela ho sebelisa khokahanyo ea DC reverse.

Tšepe e ka holim'a metsi e ka boloka khanyetso e ntle ea ho roala le ho hanyetsa kutu ho 650 ℃, 'me e na le matla a ho hanyetsa le ho hanyetsa serame le mokhathala oa mocheso.

E ka sebelisoa ho boloka khanyetso e ntle ea ho sesa le ho hanyetsa ho itseng ha kutu ha e sebetsa hoo e ka bang 650 ℃, 'me e ka ba le ts'ebetso e ntle libakeng tse hokahaneng tse chesang le tse batang.

Hlahisa lintlha

Anti-corrosion

Ho tsubella

Mabapi le rona

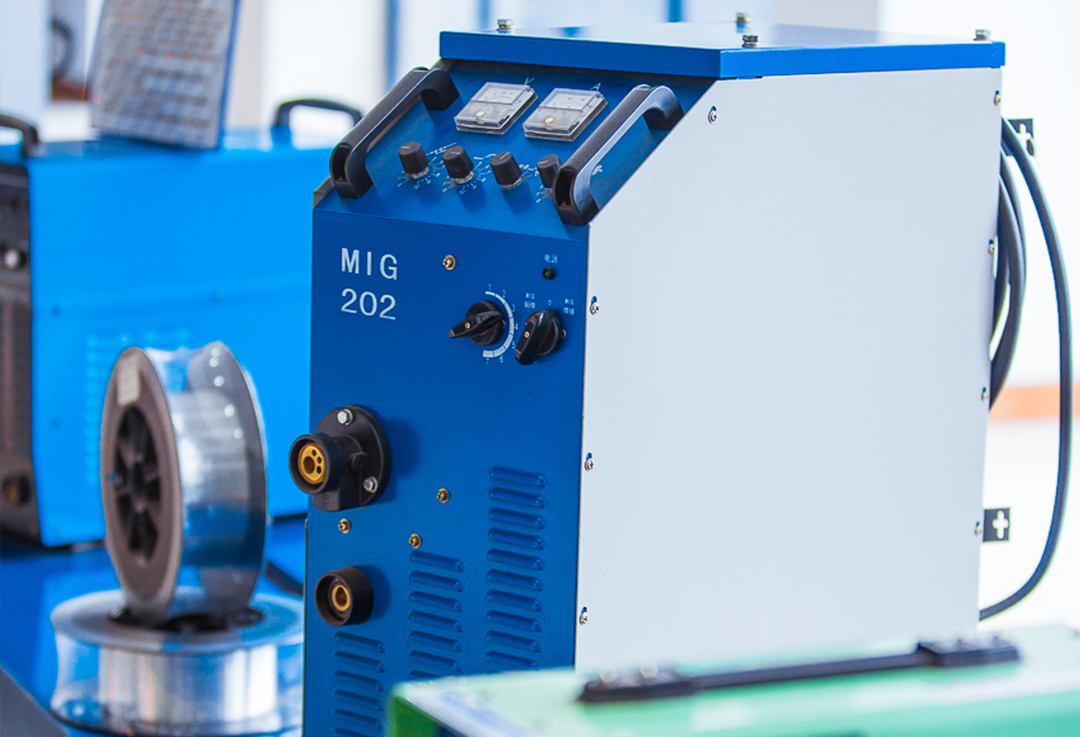

Pontšo ea fektheri ea fioor

Nyeoe ea kopo

Li-sete tse 10 tsa makotikoti a 4000m³ a chitja ho tsoa Nanjing Jinling Petrochemical

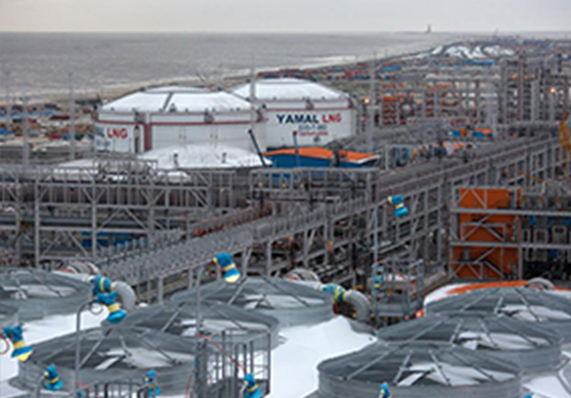

morero oa YAMAL LNG

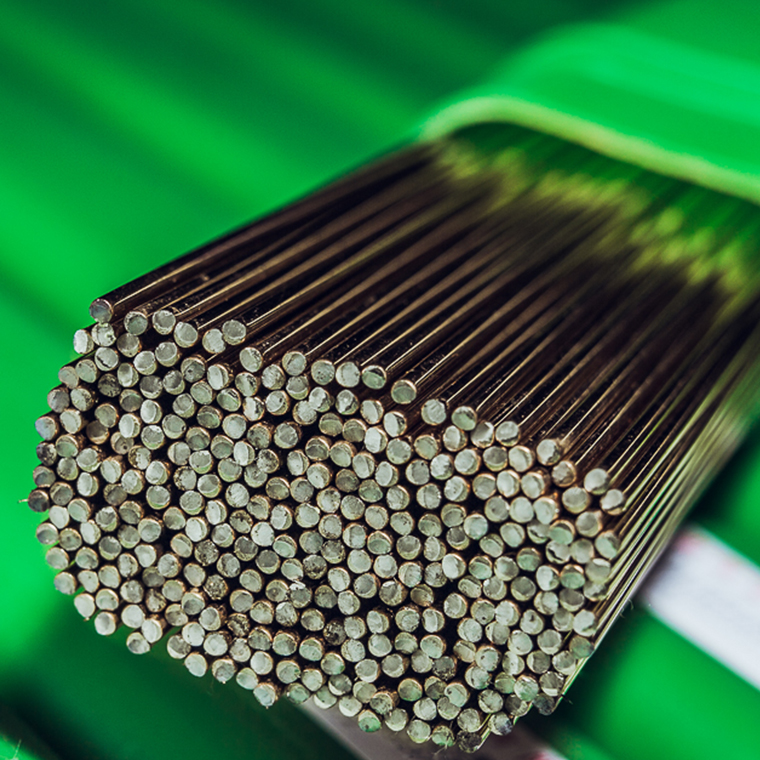

Lithunya tsa 'nete tsa feme

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T MELAO | 0.70-1,40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Margin |

| MOLAO OA MOLAO | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Margin |

| MOHLALA BOHLOKOA | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Margin |

WELD PASA THATA

Mohlala oa boleng HRC=46

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||