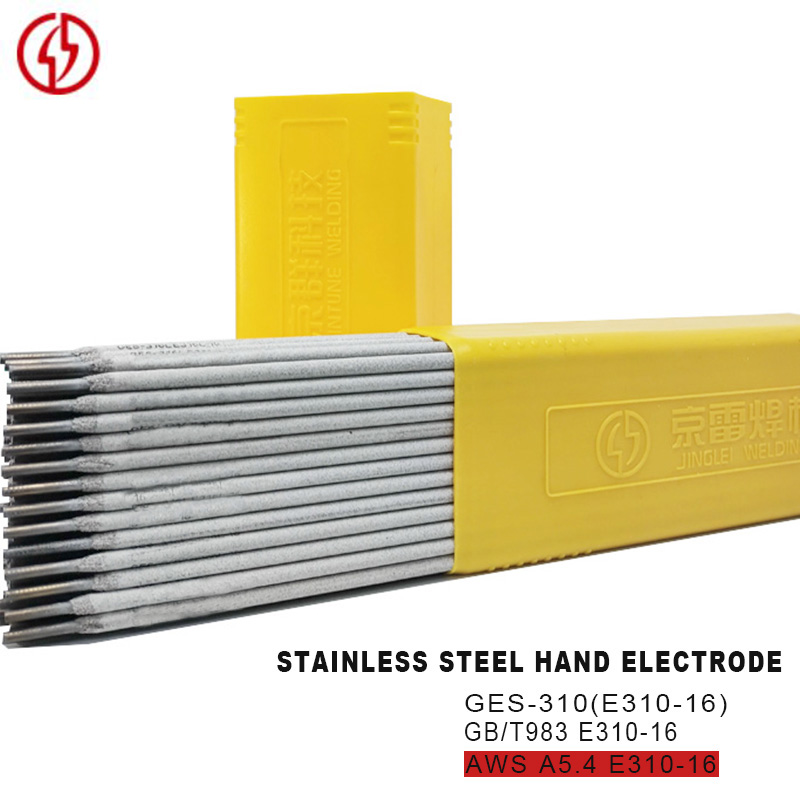

AWS E310-16 Stainless steels Manual electrode weld fabrication connection

Sesebelisoa&Tse tloahelehileng&Hloko:

Sesebelisoa&Tse tloahelehileng&Hloko:

1. E loketse lihlahisoa tse hanyetsanang le mocheso o phahameng joalo ka sebōpi sa mocheso o phahameng, lisebelisoa tsa ho pheha mashala, joalo-joalo, li ka boela tsa sebelisoa bakeng sa ho cheselletsa lintho tse sa tšoaneng.

2. Tekanyetso eo re kopaneng le eona: GB/T983 E310-16, AWS A5.4 E310-16 & A5.4M E310-16, ISO3581-A:E (25 20) R 1 2, ISO3581-B:ES310-16, JIS Z3221 ES310-16

Electrode ea tšepe e sa hloekang ea A402 ke titanium calcium e koahetsoeng ke Cr26Ni21 e hloekileng ea austenitic stainless steel electrode.Tšepe e koahetsoeng e na le khanyetso e babatsehang ea oxidation ho 900 ~ 1100 ℃.Ac-dc e sebelisoang habeli, e na le ts'ebetso e ntle ea ts'ebetso ea welding.

Electrode ea tšepe e sa hloekang e ka aroloa ka electrode ea tšepe e sa hloekang ea chromium le electrode ea tšepe e sa hloekang ea chromium, mefuta ena e 'meli ea li-electrode moo e lumellanang le maemo a naha, ho latela lipehelo tsa GB/T983-1995 tsa tlhahlobo. Chromium tšepe e sa hloekang e na le khanyetso e itseng ea kutu (oxidizing acid, organic acid, cavitation) e hanyetsa mocheso le ho hanyetsa kutu. Hangata e sebelisoa e le setsi sa motlakase, lik'hemik'hale, peterole le lisebelisoa tse ling tsa thepa.

Likaroloana

1. Titanium calcium stainless steel electrode, sebopeho se seholo ke 25% CR-20% Ni.

2. Ho hanyetsa mocheso o phahameng o tsitsitseng, ho fihlela ho 1150 ℃.

3. Arc e tsitsitseng, sebopeho se setle, li-ripples tse ntle, li-splashes tse seng kae, li-slagging tse bonolo, ho hanyetsa mollo o motle oa letlalo la lithethefatsi, ho hanyetsa hantle ha stomatal.

Lintlha tsa bohlokoa:

Oli ea bokaholimo ba tšepe, lerōle le li-sundries li tlameha ho tlosoa. Seam sa welding se lokela ho hloekisoa ka borashe ba tšepe e sa hloekang. Lehlakore le leng la likhoele tsa tšepe tse kopantsoeng le tšepe ea weld li ama boleng ba weld. Ha eleketrode e lohiloe, bophara ba lesela bo lokela ho ba ka hare ho makhetlo a 2,5 bophara ba electrode. Tšebeliso ea electrode ea chelete e tlameha ho ba 250-300 ℃ metsotso e 60 e omeletseng, ha e sebelisoa ho tlosa chelete e nyenyane ka har'a cylinder e omisang ea 100-150 ℃, ho etsa li-electrode ho lihora tse 4 ho loketse.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T MELAO | 0.08-0.20 | 1.0-2.5 | 0.75 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.030 | 0.03 | 0.75 |

| MOLAO OA MOLAO | 0.08-0.20 | 1.0-2.5 | 0.75 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.030 | 0.03 | 0.75 |

| MOHLALA BOHLOKOA | 0.097 | 2.25 | 0.4 | 26.2 | 21 | 0.3 | 0.026 | 0.004 | 0.05 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | |||||||||

| GB/T MELAO | - | 550 | - | - | 25 | |||||||||

| MOLAO OA MOLAO | - | 550 | - | - | 30 | |||||||||

| MOHLALA BOHLOKOA | - | 600 | - | - | 35 | |||||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| MOTLATSI (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

LITLHAKISO TSA PAKA:

| KARAOLI | BELELE | PCS/1KG | BOIMA/1KG | |||

| 2.0 limilimithara | 300mm | 79PCS | 2KG | |||

| 2.6 limilimithara | 300mm | 48PCS | 2KG | |||

| 3.2 limilimithara | 350 limilimithara | 27PCS | 5KG | |||

| 4.0 limilimithara | 350 limilimithara | 16PCS | 5KG | |||

| 5.0 limilimithara | 350 limilimithara | 12PCS | 5KG | |||

HLOKOMELA:

H/W: tshekaletseng boemo tjheseletsa

O/W: ho tjheseletsa maemo a hodima hlooho

Maemo a Tloaelehileng

Setifikeiti

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T MELAO | 0.08-0.20 | 1.0-2.5 | 0.75 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.030 | 0.03 | 0.75 |

| MOLAO OA MOLAO | 0.08-0.20 | 1.0-2.5 | 0.75 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.030 | 0.03 | 0.75 |

| MOHLALA BOHLOKOA | 0.097 | 2.25 | 0.4 | 26.2 | 21 | 0.3 | 0.026 | 0.004 | 0.05 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | IMAPACT BOHLOKO J/℃ | ELONGATION(%) | |||||||||

| GB/T MELAO | - | 550 | - | - | 25 | |||||||||

| MOLAO OA MOLAO | - | 550 | - | - | 30 | |||||||||

| MOHLALA BOHLOKOA | - | 600 | - | - | 35 | |||||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| MOTLATSI (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

LITLHAKISO TSA PAKA:

| KARAOLI | BELELE | PCS/1KG | BOIMA/1KG | |||

| 2.0 limilimithara | 300mm | 79PCS | 2KG | |||

| 2.6 limilimithara | 300mm | 48PCS | 2KG | |||

| 3.2 limilimithara | 350 limilimithara | 27PCS | 5KG | |||

| 4.0 limilimithara | 350 limilimithara | 16PCS | 5KG | |||

| 5.0 limilimithara | 350 limilimithara | 12PCS | 5KG | |||

HLOKOMELA:

H/W: tshekaletseng boemo tjheseletsa

O/W: ho tjheseletsa maemo a hodima hlooho