AWS A5.13 ENiCrFe-1 Nickel alloys Manual electrode Welding accessories

Kopo & Maemo

ELECTRODE ena e thehiloeng ka COBALT E KA SEBEDISWA BAKENG SA LELELEVA LA SHAFT LE SEBELE, HO CUTTING EDGE OF CHEMICAL FIBER EQUIPMENT, SAWTOOTH, SCREW PUSH ROD, HO HLOKA mocheso le HIGH Pressure valve LE pompo ea khatello e phahameng joalo-joalo. Bokaholimo ba mochini oa mosebetsi bo lokela ho ba tlase ho Ra12.5μm, 'me mafome a holim'a metsi, oli le litšila tse ling li lokela ho tlosoa ka thata. Matrix ha ea lokela ho ba le mapetsong, li-pores, lehlabathe le liphoso tse ling, 'me metse le likhutlo li lokela ho pota-potiloe. Pele o phahama, mocheso o fapaneng o lokela ho khethoa ho ea ka thepa ea substrate bakeng sa ho futhumatsa pele. Ha thepa ea matrix e le tšepe e sa keneleng mocheso kapa tšepe ea martensitic le lisebelisoa tse ling tse nang le ts'ebetso e mpe ea tjheseletsa, lera le ka holimo la tšepe le sa hloekang la austenitic le lokela ho chesetsoa holim'a matrix, ebe alloy e thehiloeng ho cobalt e lokela ho ba holimo ka mor'a ts'ebetso e boreleli. ntlafatsa ho hanyetsa mapheo le ho qoba mapetsong. Phepelo ea motlakase ea AC kapa ea DC arc e ka sebelisoa bakeng sa li-electrode tsa D802 le D812. Ho khothaletsoa phepelo ea motlakase oa dc arc.

Likaroloana

GEH-SL12 titanium calcium coated cobalt-base surfacing electrode. Cobalt-cr-tungsten alloy e sebelisoa e le terata ea mantlha. Dc reverse connection e ea khothaletsoa. Litšepe tse holim'a metsi li ka boloka khanyetso e ntle ea ho roala le ho hanyetsa kutu ho 650 ℃. Pele ho tjheseletsa, e tlameha ho behoa ka 300-350 ℃ bakeng sa hora e le 'ngoe; Lera le thata holim'a tšepe ea motheo e lokela ho tlosoa ho qoba mapetsong le brittleness. Ho ea ka boholo ba mochini oa tšepe oa motheo le mofuta oa tšepe ea motheo, e tlameha ho behoa pele ho 300-600 ℃, 'me hona joale ho loketse ho cheselletsa arc e nyenyane.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T MELAO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| MOLAO OA MOLAO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| MOHLALA BOHLOKOA | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

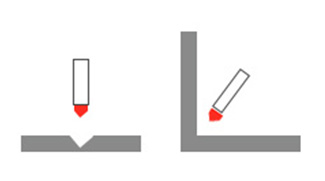

| TLHALOSO EA DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| MOTLATSI (Amp) | Ho tjheseletsa sephara/tshekaletseng | 69-95 | 70-115 | 95-145 | ||||

| Ho tjheseletsa ka ho otloloha/ho okamela | 55-80 | 65-110 | 80-130 | |||||

LIEKETSENG TS'OANE

Litifikeiti

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T MELAO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| MOLAO OA MOLAO | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| MOHLALA BOHLOKOA | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| MOTLATSI (Amp) | Ho tjheseletsa sephara/tshekaletseng | 69-95 | 70-115 | 95-145 | ||||

| Ho tjheseletsa ka ho otloloha/ho okamela | 55-80 | 65-110 | 80-130 | |||||