490Mpa Hand Electrode Bakeng sa Tšepe e Matla a Phahameng

Ts'ebeliso&E Tloaelehileng&Hlokomela

1. E Loketse HO TŠELISOA TŠEPE EA KHABONE LE TŠEPE EA KHABANE LE LOW ALLOY, MMOHO LE MATLA A TABAPILENG A BOILER, lipeipi, koloi, MOAHO, BOROHO LE LITABA tse ling, JOALOKA Q345.

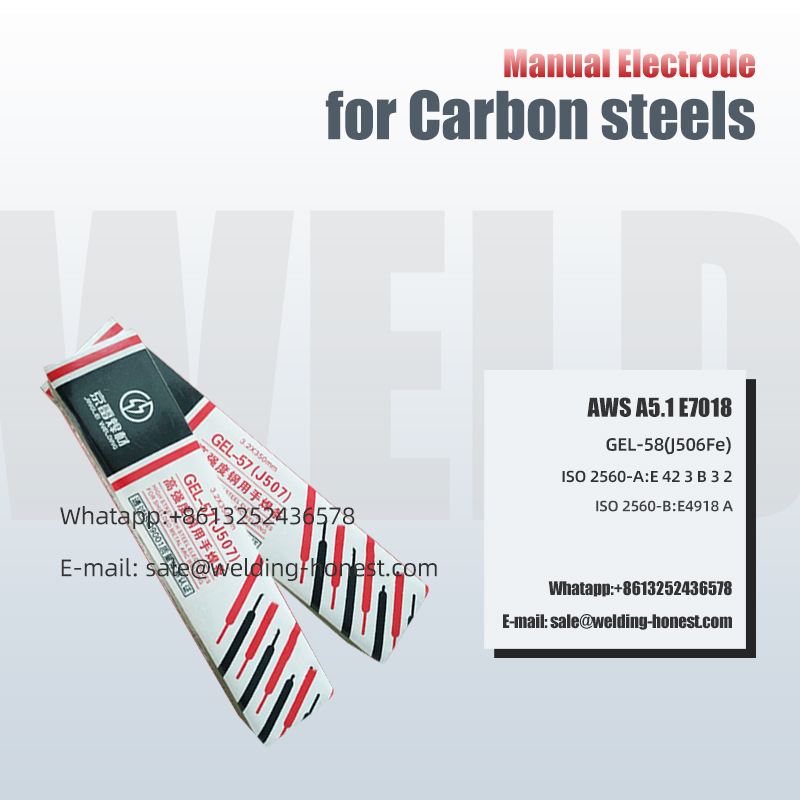

2. Tekanyetso eo re kopaneng le eona: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A:E 42 3 B 3 2, ISO 2560-B: E4918 A

Kaha electrode ea E7018 e monya mongobo habonolo, e bolokiloe ka ontong ea ho omisa electrode. Electrode e bolokiloeng moeeng e ka khutlisetsoa ho 350 ~ 400 ℃ bakeng sa 1h ~ 2h. E le ho tsosolosa thepa ea letlalo. Tšepe e bonolo e ka tšeloa ka li-electrode tsa E7018 tse sa behoang, empa matla a ho qetela a ka 'na a se ke a lekana ka ho lekaneng.

Likaroloana

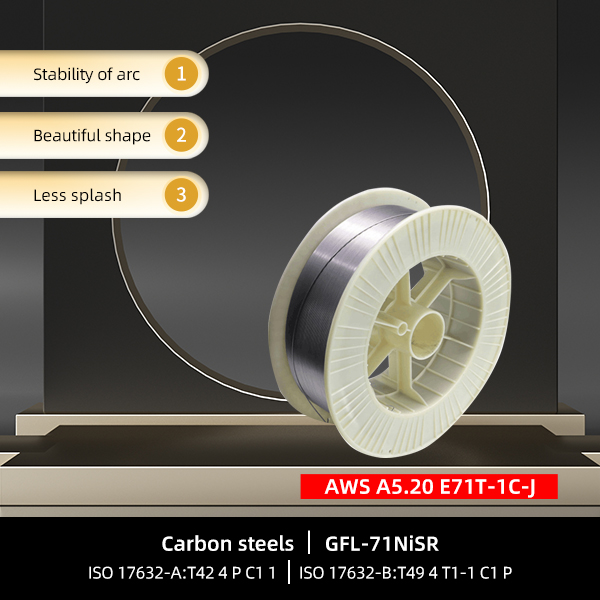

Iron powder low hydrogen mofuta oa elektrode ea letsoho, ts'ebetso e phahameng ea welding, arc e tsitsitseng, sebopeho se setle, corrugations, ho phatloha ho honyenyane, de-slagging e bonolo, ho hanyetsa mollo oa letlalo la lithethefatsi hantle, ho hanyetsa stomatal. Thepa e tsitsitseng ea mochini, polasetiki e ntle le mocheso o tlase o ama ho tiea.

E7018 ke elektrode ea tšepe ea boleng bo holimo e nang le phofshoana ea tšepe e tlase ea hydrogen potasiamo. Electrode e na le ts'ebetso e ntle ea ts'ebetso ea welding, ho satalla ha arc ho lokile, ha ho bonolo ho hlahisa leeme la khoheli ho foka, seam welding se etsa se hloekile ebile se le setle, ho phatloha ho fokolang, slag e bonolo; The weld tšepe na le babatsehang le tsitsitseng tlaase mocheso toughness le crack resistance. Tšebeliso ea bobeli ea Ac le DC, e ka tsoela pele ho tjheseletsa boemo bohle. Tšobotsi ea eona ke hore letlalo la lithethefatsi le na le phofo ea tšepe, e ka fokotsang palo ea likarolo tsa welding. Apeha electrode ka likhato tse 350 ~ 400 tsa Celsius bakeng sa lihora tse 1 ~ 2, 'me u sebelise ha u baka. Ka kakaretso elektrode ena ea boleng bo holimo e sebelisoa bakeng sa tšepe ea ho tjheseletsa sekepe (A, B, D kapa E, A36, E36) le meaho ea bohlokoa ea tšepe e nang le alloy e tlase ea matla a lekanang, joalo ka liboilers, likepe tsa khatello le sethala sa ho cheka kantle ho naha, etc.

Khampani & Feme

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| MOLAO OA MOLAO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| MOHLALA BOHLOKOA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | ELONGATION(%) | ||||||

| GB/T MELAO | 400 | 490 | AW | 20 | ||||||

| MOLAO OA MOLAO | 400 | 490 | AW | 22 | ||||||

| MOHLALA BOHLOKOA | 460 | 555 | AW | 30 | ||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

HLOKOMELA:

H/W: tshekaletseng boemo tjheseletsa

O/W: ho tjheseletsa maemo a hodima hlooho

Maemo a Tloaelehileng

Setifikeiti

Sebopeho sa sehlahisoa le thepa ea mechine selelekela

KIKEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T MELAO | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| MOLAO OA MOLAO | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| MOHLALA BOHLOKOA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

MOSEBETSI OA MECHI:

| LETLOTLO | MATLA A KOPA(MPa) | MATLA A KEKETSO(MPa) | HEATTREAMENT℃xh | ELONGATION(%) | ||||||

| GB/T MELAO | 400 | 490 | AW | 20 | ||||||

| MOLAO OA MOLAO | 400 | 490 | AW | 22 | ||||||

| MOHLALA BOHLOKOA | 460 | 555 | AW | 30 | ||||||

LITLHAKISO TSA TŠEBELETSO TSE KHOTHATSANG:

| TLHALOSO EA DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| MOTLATSI | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

HLOKOMELA:

H/W: tshekaletseng boemo tjheseletsa

O/W: ho tjheseletsa maemo a hodima hlooho